Abstract

The tritium required for ITER will be supplied from the CANDU production in Ontario, but while Ontario may be able to supply 8 kg for a DEMO fusion reactor in the mid-2050s, it will not be able to provide 10 kg at any realistic starting time. The tritium required to start DEMO will depend on advances in plasma fuelling efficiency, burnup fraction, and tritium processing technology. It is in theory possible to start up a fusion reactor with little or no tritium, but at an estimated cost of $2 billion per kilogram of tritium saved, it is not economically sensible.

Some heavy water reactor tritium production scenarios with varying degrees of optimism are presented, with the assumption that only Canada, the Republic of Korea, and Romania make tritium available to the fusion community. Results for the tritium available for DEMO in 2055 range from zero to 30 kg.

CANDU and similar heavy water reactors could in theory generate additional tritium in a number of ways: (a) adjuster rods containing lithium could be used, giving 0.13 kg per year per reactor; (b) a fuel bundle with a burnable absorber has been designed for CANDU reactors, which might be adapted for tritium production; (c) tritium production could be increased by 0.05 kg per year per reactor by doping the moderator with lithium-6. If a fusion reactor is started up around 2055, governments in Canada, Argentina, China, India, South Korea and Romania will have the opportunity in the years leading up to that to take appropriate steps: (a) build, refurbish or upgrade tritium extraction facilities; (b) extend the lives of heavy water reactors, or build new ones; (c) reduce tritium sales; (d) boost tritium production in the remaining heavy water reactors.

All of the alternative production methods considered have serious economic and regulatory drawbacks, and the risk of diversion of tritium or lithium-6 would also be a major concern. There are likely to be serious problems with supplying tritium for future fusion reactors.

Export citation and abstract BibTeX RIS

1. Introduction

The tritium available commercially from the Canadian reactor production programme after the retirement of ITER may not be sufficient to start DEMO [1]. Two factors make the tritium supply for DEMO even smaller than previously considered. Firstly, ITER will be severely delayed, and if DEMO is similarly delayed then all the Canadian CANDU reactors will have been shut down, while the civilian tritium stockpile will have undergone decay. Secondly, it is conceivable that more than one fusion reactor will be built after ITER—for example, one or more power reactors, and/or one or more neutron sources. The tritium required to start up is uncertain within a wide margin; stocks would likely have to be shared if more than one fusion reactor is built. Of previous studies of tritium resources [1–3], the most recent [1], using a now outdated schedule for ITER, looked at existing tritium removal facilities in Canada and Korea, as well as accelerators, commercial light water reactors and accelerator driven subcritical systems, considering a single reactor design (FDS-II). Given that ITER will not start tritium operations before 2036, DEMO is very unlikely to start up before 2055, so we are only interested in tritium production and consumption after about 2020. Current stocks are of little relevance.

The US has started producing tritium for defence purposes by irradiating tritium-producing burnable absorber rods containing lithium in a commercial (government-owned) light water power reactor. In theory, a lack of tritium could be overcome at any time, since it can be generated in any fission reactor, but the technical, political and economic issues associated with doing so are significant.

2. Tritium required for start-up of a fusion reactor

2.1. Start-up with 50% tritium

Estimation of the amount of tritium required to start up a reactor is a non-trivial exercise. Abdou et al point out that the tritium inventory must provide a reserve necessary to continue reactor operation if the tritium processing system fails for a short time [4, 5]. They conclude that the fuelling and exhaust processing circuit dominates, because the burn-up will be low. For their example of a reactor with 3000 MW fusion power, if the product of the fuelling efficiency and burnup fraction is 1%, the tritium processing time is 6 h, and the reserve time is 6 h, then start-up needs about 21 kg. The research priorities are therefore to improve plasma fuelling efficiency, burnup fraction, and tritium processing technology.

Not only do the values given in the literature for specific reactors vary widely from 0.5 to 18 kg [1, 6] (although the low end of this range seems implausible, given the 21 kg estimate above), but there remains the possibility that some major cause of tritium retention has been neglected, perhaps because of unexpected trapping sites due to radiation damage, intrinsic impurities or transmuted atoms.

2.2. Start-up with deuterium-rich or pure deuterium fuel

Zheng et al [7] and Kasada et al [6] proposed that a fusion reactor could be started up without an external supply of tritium, by fuelling it initially with deuterium, and gradually increasing the proportion of tritium. This would certainly pose problems in tokamak physics: the reactor has to run at a whole series of power levels, all with different compositions, heating power requirements, and stability properties. Their proposal requires up to 170 MW of deposited neutral beam power, which may exceed the amount that needs to be installed anyway for pushing the DT plasma through the L–H transition.

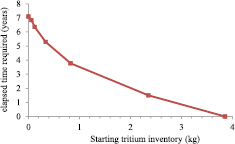

We have made a new estimate of the length of time required to start a reactor up with less than 50% tritium. We start with assumptions concerning the fuelling and breeding systems, given in figure 1. These parameters optimistically imply that the total tritium inventory at 50% T operation is only 3.9 kg. The plasma simulation code TRANSP was used to obtain the rates of DD and DT fusion power at various tritium levels (table 1).

Table 1. Fusion rates for different tritium fractions.

| Tritium atomic % | Fusion power (MW) | DT fusion rate (s−1) | DD fusion rate (s−1) |

|---|---|---|---|

| 1 | 44 | 1.3 × 1019 | 1.1 × 1019 |

| 2 | 83 | 2.7 × 1019 | 1.2 × 1019 |

| 5 | 217 | 7.4 × 1019 | 1.3 × 1019 |

| 10 | 520 | 1.8 × 1020 | 1.4 × 1019 |

| 25 | 1468 | 5.2 × 1020 | 1.3 × 1019 |

| 50 | 2398 | 8.5 × 1020 | 8.4 × 1018 |

Figure 1. Elapsed time required before full power 50%D–50%T operation can start, as a function of the tritium available for start-up. Assumptions: burn-up = 2%, tritium breeding ratio for DT reactions = 1.1, tritium production ratio for DD reactions = 0.72, tritium residence time in the breeding system = 3 h, tritium residence time in fuelling system = 5 h, zero tritium loss other than decay, zero retention, availability = 30%.

Download figure:

Standard image High-resolution imageFigure 1 shows the elapsed time required for a given starting tritium inventory. To start up at 1% tritium in the plasma (61 g inventory) the plant needs to be operated for 6.8 elapsed years before reaching 50% tritium operation. Start-up at 10% (830 g inventory) needs only 3.8 elapsed years. It is possible in theory to start with no tritium at all, but in this case significant tritium from DD fusion would accumulate in the plasma during the first few seconds. The amount of tritium saved by starting with no tritium at all compared to 10% is only 830 g.

Table 2 shows the economic consequences if DEMO is started with only 10% tritium in the plasma. The interest payments accruing during the tritium accumulation phase (with no power generated) would be $6 billion, or $1.9 million per gram of tritium saved. In addition, the electricity alone costs $96 000 per gram of tritium saved. It is not economically sensible to start up DEMO with much less than 50% tritium in the plasma.

Table 2. The cost implications for starting a fusion reactor starting at 10% tritium. NBI power: 125 MW at 10%, 100 MW at 25% (estimate). Wall plug efficiency of the heating system = 40%, zero electrical consumption apart from heating, capital cost = $30 billion, interest rate = 5%. Operational costs neglected. Other assumptions are given in figure 1.

| Tritium (T) residence time in fuelling system (h) | 5 |

| Electricity to start up at 10% T (MWh) | 2.85 × 106 |

| Assumed market rate of electricity ($/MWh) | 100 |

| Cost of electricity to start up in 10% T at market rate | $290 million |

| Nominal DEMO power output | 500 MWe |

| Elapsed time during start-up | 3.8 y |

| T required to start up machine in DT from day 1 | 3.9 kg |

| T required to start up machine in 10% T | 0.8 kg |

| T saved | 3.0 kg |

| Interest cost per year | $1.5 billion yr−1 |

| Electricity cost per unit mass of T saved | $96 million kg−1 |

| Interest plus electricity cost per unit mass of T saved | $2.0 billion kg−1 |

Konishi et al [8] argue that years of low power tests will be required before reaching full power, and that if these are carried out with DD or low T/D ratio, then the required tritium could be bred with no additional costs or time. They estimate that ~5 years of D–D commissioning would be enough to create an inventory of ~3–5 kg of T [9]. However, table 2 shows that even if the interest cost is ignored, on the basis that commissioning is needed in any case, electricity alone is $96 000 per gram of T saved. We suspect that if adequate tritium is available, then commissioning would be best done using 50% T at gradually increasing power. If this is correct then the electricity required for DD commissioning is attributable to need to make tritium.

3. ITER and other tritium users

We have obtained an unofficial estimate for the ITER tritium requirements schedule, starting around 2036, and totalling 12.3 kg. The so-called National Ignition Facility is limited to a total tritium inventory of 0.83 g (8000 Ci) [10]. If we assume that consumption by fusion will be small, and that tritium used will be effectively recycled, we can safely neglect NIF as a tritium consumer. JET is expecting to buy 55 g for its next and final tritium campaign, and can also be neglected. Ontario Power Generation (OPG) usually sells about 0.1 kg yr−1 [11, 12]. SRB (Canada) Inc., a manufacturer of gaseous tritium light sources, uses about 80 g yr−1 [13]. The development of high power LED lights has probably affected the market in tritium lights, and it does not seem that they have been widely accepted for runway lighting [14]. Below we have assumed 100–300 g yr−1 sales by OPG.

4. Tritium production: heavy water reactors

Reactors using heavy water as moderator, coolant, or both, inevitably generate tritium due to neutron capture by deuterium. While this is no longer a popular technology in most countries, Romania, Argentina and India are still building and planning further plants, and a new heavy water design, the Advanced Fuel Candu Reactor, is under development in Canada and China [15].

OPG operates a Tritium Removal Facility (TRF) at its Darlington nuclear station. This facility extracts tritium from the moderator water of all of OPG's CANDU reactors (not just the four at Darlington). Ni et al [1] estimate that one CANDU 6 reactor can produce 130 g of tritium per year, but this is based on physics, not actual production data.

The production of tritium at Darlington depends on continued operation of CANDU reactors in Ontario. Extraction of tritium turns a radioactive contaminant into a valuable product. Moreover, OPG is required to limit the tritium concentration in the moderator and coolant, so they are obliged to keep the TRF in operation as long they have CANDU reactors operating. Ontario does not intend to proceed with the construction of two new reactors at the Darlington Generating Station, although they state that they continue to have the option to build new reactors in the future. (There is one CANDU reactor in the Canadian province of New Brunswick, but its operator is only required to remove tritium from the coolant, not from the moderator, so they send very little heavy water for detritiation, and are not included in our analysis.)

To date, five reactors have been refurbished in Canada [16]. Refurbishment is intended to extend the reactor's life for an additional 25–30 years [16, 17], although (1) suggests 20 years. This means that 60 year lifespan (from commissioning to decommissioning) in both Canada and Korea remains possible. In a revision to the 2013 plan, six reactors at the Pickering Generating Station are now expected to be in service until 2022—2024. Refurbishment is planned to begin at both Darlington and Bruce Generating Stations in 2016, and in fact Darlington unit 2 was taken off line on 14 October 2016 ready for work to begin. The new Korean government recently stated its intentions to halt all new build nuclear power plants and put an end to life extensions [18]. This may not occur (due to feasibility and/or shifts in government and government policy), but it does mean that the prospects of Korean HWRs being refurbished in future are slimmer than before.

While India certainly has tritium extraction facilities, it is not clear that any tritium is commercially available, although in future this would be theoretically possible. Romania plans to build a TRF at Cernavoda, to reduce releases and worker doses during reactor refurbishment [19]. Other countries may make the same decision when preparing for refurbishment or decommissioning. Tritium removal technology is being pursued actively in connection with the Fukushima clean-up. ITER and DEMO will also encourage the development of water detritiation technology. It is reported that cryogenic distillation technology can greatly reduce the size and cost of tritium removal equipment [20], making detritiation attractive even for a single reactor.

4.1. Scenarios

The actual tritium production rate varies from reactor to reactor. Various estimates for tritium production in HWRs are to be found in the literature, ranging from 0.21 to 0.26 kg/GWe/full-power year [1, 21], which agrees well with the data from Cernavoda reactors in Romania (0.22 kg/GWe/fpy).

In the analysis below, the tritium production has been estimated from the historical data up to 2015 from the net electric output at a rate of 0.228 kg/GWe/fpy or 2.543 × 10−5 kg/GWhe. The electricity delivered to the grid may not be the best guide to the fission rate, as the efficiency of conversion of heat to electricity is not constant, and there may be times when the reactor is operating but not producing electricity at all; however the data are available and give a reasonable estimate of the tritium produced. For the years beyond 2015, an average historical capacity factor for each plant (excluding years of low or zero capacity factors—usually during or around refurbishments) and the reference unit power as of 2015 were taken to estimate the electricity production in future, and hence tritium production. HWR lifetime before refurbishment is assumed to be 30 years in all cases, and refurbishment is assumed to extend the reactor life by 25 years from the point when it is brought back online.

Figure 2 shows the estimated T generation by commercial HWRs for all countries, and the resulting national and global inventories. The data shown represent the estimated quantities of tritium from HWR production, ignoring whether the tritium is actively extracted, released to the environment, used in national defence programmes, or sold commercially.

Figure 2. Global T production in all commercial HWRs and resulting inventories. Refurbishments of existing reactors in future are assumed in Canada, the Republic of Korea, and Romania (see 'Scenario B' in the text for details). In India, Kakrapar-3 and 4 and Rajasthan-7 and 8 are constructed according to present plans [22].

Download figure:

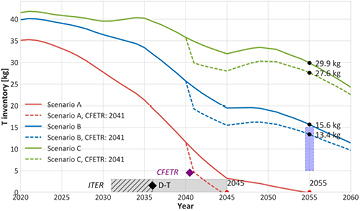

Standard image High-resolution imageBelow we assume that only Canada, the Republic of Korea, and Romania extract their tritium and make it available for nuclear fusion purposes. Figure 3 shows the forecast tritium stockpiles for these countries. Commercial sales at present only occur in Canada, to the authors' knowledge. The Canadian government does not sell tritium for military purposes in the US or elsewhere, and we assume that this remains the case. The following three scenarios are defined:

Figure 3. Forecast tritium stockpiles for Canada, South Korea and Romania, for scenarios A, B and C. No consumption from fusion is shown.

Download figure:

Standard image High-resolution imageScenario A—pessimistic:

- All existing plants in Canada and the Republic of Korea complete their assumed operational life (30 years from first connection to the grid, or 25 years after their refurbishment).

- Darlington-2 (presently underway) and Bruce-6 refurbishments go ahead according to schedule. No other HWR refurbishments go ahead in Canada (the Ontario government is very clear that the full programme will only be carried out if the first refurbishments are carried out within a reasonable time and budget.)

- No refurbishments occur in the Republic of Korea, and the planned refurbishments of Cernavoda-1 and Cernavoda-2 in Romania do not go ahead, and as such a TRF is not built in Romania. (The main purpose of constructing a TRF in Romania is to enable the refurbishment of the Cernavoda reactors.) Thus, in this pessimistic scenario, no tritium is available from Romania.

- Commercial sales take place at 0.3 kg yr−1, in Canada only.

Scenario B—moderate:

- All existing plants in Canada, the Republic of Korea, and Romania complete their assumed operational life (30 years from first connection to the grid, or 25 years after their refurbishment).

- The following reactors in Canada are refurbished according to schedule [23, 24]: Darlington-1, 2, 3, and 4, Bruce-3, 5 and 6.

- A TRF is built in Romania, and Cernavoda-1 and 2 are refurbished.

- In Korea, Wolsong-2 is refurbished after 30 years of operation.

- Commercial sales take place at 0.2 kg yr−1, in Canada only.

Scenario C—optimistic:

- All presently planned CANDU refurbishments in Canada go ahead (all four Darlington units, and all six Bruce units which have not yet been refurbished).

- In Romania, a TRF is built in the 2020s to facilitate the refurbishment of Cernavoda-1 and Cernavoda-2, which are refurbished to schedule. Cernavoda-3 and 4 are constructed and refurbished after 30 years of operation, extending their lives a further 25 years—well into the 2070s.

- Wolsong-2, 3, and 4 are refurbished after 30 years of operation.

- Commercial sales take place at 0.1 kg yr−1, in Canada only.

All scenarios:

- In Canada, Gentilly-2 and Point Lepreau do not detritiate their moderators.

- Wolsong-1 in the Republic of Korea is shut down permanently in 2022. The Korean government recently stated that it intends to shut Wolsong-1 down 'as soon as possible' [18]. It is significantly older that the other Korean HWRs, and appears to have had some problems following its recent refurbishment (it was taken offline for two years after refurbishment and has operated at a load factor of ~50% since).

The forecast combined tritium stockpile in these three countries is shown below, in the case where ITER D–T plasma operations start in 2036—the presently scheduled date—(figure 4), and 2040 (figure 5). The ITER consumption profile mentioned in section 3 is used, with start of D–T plasma taken as the point at which deliveries to site reach 0.5 kg.

Figure 4. Total tritium stockpile in Canada, Romania, and Republic of Korea, with ITER D–T operations commencing in 2036. Comparatively small amounts of T are required beforehand for T–T and commissioning operations (shown in the hatched region). The shaded blue region shows a potential DEMO demand of between 5 and 15 kg of T in 2055, with the black markers indicating how much tritium is available for the given scenario, or a red marker indicating the date at which the stockpile is depleted.

Download figure:

Standard image High-resolution imageFigure 5. Total tritium stockpile in Canada, Romania, and Republic of Korea, with ITER D–T operations commencing in 2040. CFETR consumption is assumed to take place five years later, in 2045.

Download figure:

Standard image High-resolution imageWith plans for fusion reactors with large scale consumption of tritium already on the horizon both in China—the Chinese Fusion Engineering Test Reactor (CFETR), and in the US—the Fusion Nuclear Science Facility (FNSF), the fusion demand for tritium could be significant in the 2040s onwards. There are large uncertainties concerning the existence of these reactors, and the amount of tritium they may require to start-up. As such, a simple one-time 'purchase' of 5 kg of tritium is shown five years after the start of ITER D–T operations, to show the impact on the supply for DEMO. The start date for tritium burn by DEMO has been taken to be 2055.

If only OPG is assumed to supply tritium for the fusion community, in scenario A there would be just enough tritium to complete ITER's planned D–T operations, and in scenarios B and C, OPG would potentially be able to supply 8.1 kg, and 16 kg in 2055, respectively—ignoring any potential consumption from CFETR or FNSF.

Our results differ from those of (1), who estimate that between ~7 and ~32 kg of T in Canada and South Korea will remain in 2050. This is partly because Ni et al assumed that ITER D–T operations start in 2021, whereas we assume 2035 or 2040.

Of course, all these predictions are speculative, and many events have the potential to disrupt this picture. India could continue its push for more nuclear power and build further HWRs (4 are presently under construction—with higher nameplate capacities than existing Indian HWRs) and could decide to build a TRF specifically to service its HWR fleet and enable easier refurbishment. It might in future make the tritium commercially available. On the other hand, it may choose to keep a strategic stockpile of tritium. Equally, the Republic of Korea could choose to hold on to its tritium for its national fusion research programme (their drive for nuclear fusion research is, after all, enshrined in law). A serious nuclear accident/event at a power plant could also affect tritium production; in 2011, Fukushima saw Germany pledge to shut down all its remaining nuclear power plants (totalling 10.8 GWe, approx. 20% of the national supply) by 2022.

4.2. Tritium-producing fuel rods

CANDU reactors do not have burnable absorbers, because they are fuelled with natural uranium which has very little reactivity margin. However, CANDU designers have considered using burnable absorbers, in combination with enriched fuels, to reduce the positive void reactivity. The so-called 'low void reactivity fuel bundle' (LVRF or CANFLEX-LVRF) uses a burnable absorber located in the central element of the bundle, and has undergone considerable development, although it has not been put into use [25]. Recent papers on burnable absorbers in CANDU have come mostly from Korea and Romania [26, 27], but none discuss tritium production. There is apparently one unpublished study of the use of lithium in CANDU fuel assemblies, producing about 0.2 kg/GWe-y even with natural uranium [2].

The problem of permeation of tritium from the rods is likely to be less significant in a heavy water machine. The tritium routinely created in a CANDU reactor coolant alone is about 1.7 g yr−1, compared to 0.3 g yr−1 leaking into the coolant of a PWR from the tritium-producing burnable absorber rods described in section 6 below. Note that most of the world's heavy water reactors do not have any tritium removal facilities at all, and even in Canada the Point Lepreau and Gentilly reactors do not detritiate their moderator. This shows that CANDU machines are routinely able to run with five times as much tritium entering the coolant as is permitted for a PWR in the USA, even with no detritiation. The likelihood of a major change to the fuel composition being accepted for existing plants is low, but further CANDU machines are planned, so this may still be a realistic possibility.

4.3. Tritium-producing adjuster rods

Adjuster rods are used in the CANDU reactor to optimize the neutron flux profile for reactor power, compensate for fuel burnup, and provide excess reactivity to overcome xenon-135 surges following a power reduction. Cobalt-60 is produced in CANDU reactors by replacing the stainless steel adjuster rods with neutronically equivalent cobalt-59 adjusters. Countries that use CANDU reactors for this purpose include Canada, Argentina, China and South Korea [28]. The standard CANDU core has 21 adjuster rods. They are normally in-core, and are driven out (vertically) when extra positive reactivity is required, either when refuelling is unavailable, or to override xenon build-up. The reactivity worth of the complete system is about 0.015. The adjusters also help to flatten the power distribution, so that more total power can be produced without exceeding channel and bundle power limits.

One reactor can produce 1 × 1017 Bq of 60Co per year [29]. If adjuster rods containing lithium were used instead, and the same number of atoms of tritium could be made, this would give 0.13 kg per year, easily matching the production from heavy water. The reactivity used up for this production rate is about 5 mk, one third of the theoretical maximum. If one is willing to sacrifice burnup slightly, one could refuel at a higher frequency, providing up to 15 mk of reactivity, giving 0.40 kg yr−1 [30]. Additional reactivity can also be achieved by using higher purity heavy water. The permeation of tritium from the rods might require special-purpose hardware for removing the rods from the core.

This approach may minimize the required changes to the design and operating procedures of a CANDU reactor

4.4. Lithium in moderator

If a heavy water reactor is already equipped with a detritiation facility, the tritium production rate could be increased by doping the moderator with lithium. The tritium production cross-section of lithium-6 is six orders of magnitude higher than for deuterium, so only a modest concentration of lithium is required. Moderator poison is routinely used to compensate for excess reactivity [25, 31] in the initial core, when all fuel in the core is fresh, and during and following reactor shutdown, when the 135Xe concentration has decayed below normal levels. Boron, in the form of boric acid, is used in the initial core, and gadolinium is used following reactor shutdown. Gadolinium has the advantage that its burnout rate compensates for xenon growth.

If we choose as a target to double the normal tritium generation rate, the concentration of natural lithium in the moderator would be 2.5 mg kg−1, or just 0.16 mg kg−1 for pure 6Li. In comparison, the concentration of gadolinium can range from zero to ~1 mg kg−1, although the latter amount would only be used after a shutdown. If enough lithium is used to double tritium production, the absorption by gadolinium (at its maximum concentration) is still 12 times as much as by lithium. While the tritium concentration might be higher than otherwise, note that most of the world's heavy water reactors operate with no detritiation, with some discharging more than trace amounts into the environment.

The lithium content would be adjusted to maintain the correct reactivity. Suitable water chemistry must be maintained, and the safety case would have to be re-evaluated. Some candidate lithium compounds are shown in table 3 below. For nitrate ions the upper limit seems to be about 0.5 mg kg−1, allowing only 0.06 mg kg−1 of lithium, which is not sufficient. We have not been able to establish true upper limits on the concentrations of other anions, but if similar limits apply then they would also be unsuitable.

Table 3. Candidate lithium compounds and comments on their suitability for the CANDU moderator [31].

| Lithium nitrate | LiNO3 | Promotes radiolytic decomposition of D2O. Maximum nitrate concentration ~0.5 mg kg−1, allowing only 0.06 mg kg−1 of lithium—not sufficient |

| Lithium hydroxide | LiOH | Lithium hydroxide is used in the primary coolant to make the water more alkaline for corrosion control, at 0.35–0.55 mg kg−1 of Li, with pHa (apparent pH) = 10.2–10.4 [25] |

| Lithium deuteroxide | LiOD | Similar to LiOH, but neutron loss to hydrogen is minimized by using deuterium instead of hydrogen |

| Lithium borate | Li2B4O7 | Also known as lithium tetraborate See discussion below |

| Lithium sulphate | Li2SO4 | Sulphur species may promote localized corrosion of alloy components [25]. Sulphate ions do not form reactive intermediates with short-lived radiolysis products, so it does not promote the radiolytic decomposition of D2O |

| Lithium carbonate | Li2CO3 | Carbonate anions are readily converted to oxalate through combination with primary water radiolysis radicals. The oxalate anion can combine with gadolinium, leading to precipitation of gadolinium oxalate salt throughout the moderator system |

| Lithium chloride | LiCl | Chloride promotes stress corrosion cracking of stainless steel, and radiolytic decomposition of D2O. Target < 0.1 ppm |

| Lithium fluoride | LiF | Fluoride promotes stress corrosion cracking of stainless steel, corrosion of zirconium alloys, and radiolytic decomposition of D2O |

| Lithium nitrite | LiNO2 | Used in concrete to protect steel from corrosion |

However, boric acid (H3BO3) is already used as a method of reactivity control, and apparently does not promote the formation of D2 gas [32]. It might be possible to use lithium hydroxide or lithium deuteroxide in combination with boric acid. In the appropriate molar ratio they will form lithium borate, but the ratio in solution can be varied. In fact this combination (with lithium depleted in 6Li) is used in PWR plants to control reactivity and pH. It gives an alkaline solution unless the boric acid is present in very large excess. When using gadolinium it is important to maintain slightly acidic conditions in the moderator to prevent the precipitation of gadolinium hydroxide [25]. Consequently boric acid/lithium hydroxide could only be used if no gadolinium was present.

If pure 6Li is used, and the lithium and boron together consume 5 mk of neutrons as estimated in section 4.4 above, then 0.051 kg yr−1 of tritium would be generated. More could be produced if lithium hydroxide was supplied in excess, giving a more alkaline moderator. More could also be produced if the neutrons available could be pushed nearer to the 15 mk available in principle by pulling out the adjuster rods, although this would give a less uniform power distribution, reducing the fuel burn-up. At first sight the physics and chemistry of 6Li doping in the moderator seem promising enough to justify further investigation to identify any show-stoppers and determine whether the financial and licensing implications are acceptable. This might be a practical way of stretching a small number of CANDU reactors with modest cost.

5. Tritium production: reprocessing, particle accelerators and research reactors

Tritium is produced in fission reactions, so it is a by-product of the reprocessing of nuclear fuel. In theory ongoing and planned worldwide reprocessing activities could lead to the extraction of 0.3 kg yr−1, using 5 × 10−5 kg/ton-U [2]. However, today's plants do not capture tritium, but simply discharge it to the environment. The presence of other radionuclides would complicate the process. The expense and probable tritium losses involved in handling thousands of tons of fuel would be considerable. In some countries there is a preference for storing spent fuel for many years at the reactor site before processing, during which time much of the tritium would decay. Tritium supply from reprocessing is uneconomical and therefore infeasible.

The US government has estimated that accelerator production of tritium at 1.5 kg yr−1 would require a capital cost of $2.8 billion, with a total undiscounted cost over its 40 year life of $7.5 billion (1999 dollars). We suspect that the accelerator option was from the start a product of the US military/industrial/scientific lobby.

While research reactors are smaller than power reactors, they have the advantage that they are licensed to irradiate a wide range of samples. We have estimated the amount of tritium that could be produced in two ways: by calculating the neutrons absorbed by a standard uranium irradiation sample [33], as designed for the Jules Horowitz reactor under construction at Cadarache, and by comparison with the rate of production of 99Mo at the HFR in the Netherlands [34]. Both estimates give 2 g yr−1 of tritium. The Japan Atomic Energy Research Institute (JAERI) actually started producing tritium on a trial basis with the stated aim of supplying tritium for a fusion reactor [35, 36]. Unfortunately the authors do not say how many targets were irradiated at one time, making it impossible to estimate the tritium production rate.

6. Tritium production: commercial light water reactors

The US government is already using commercial light water reactors for tritium production for bombs, using tritium-producing burnable absorber rods (TPBARs). The Tritium Extraction Facility at Savannah River, used for this purpose, which began operations in 2007, cost nearly $500 million to build and approximately $30 million per year to operate. The agreement between DOE (Department of Energy) and TVA (Tennessee Valley Authority) provided a basis for TVA to proceed with preparing amendments to the NRC licenses for their reactors. The agreement, negotiated at cost price, will run through 2035 and has a value of approximately $680 million. (The value over the full 35 year term was approximately $1.5 billion (48)). Note that savings were made by using some existing Savannah River facilities. Any reactor producing tritium would need a revised operating license. The task was made easier because the TVA's statutory charter assigns it a national security mission, and TVA's reactors are already government facilities. Neither of these statements would be true of most reactors in western countries today. Although tritium production could be performed in many reactors without significant modifications, there would be small changes to the reactivity profile, and occupational doses might increase. The regulators would be extremely reluctant to permit this.

The cost for production at light water reactors was estimated [37] to be $40 million—$60 million per kg (1999 dollars)—much greater than the $25 000/g currently charged by OPG. A civilian programme might save money if the DOE or TVA facilities could be used, provided the US government writes off its capital investment. The production rate is limited in part by the tritium permeation into the coolant, not by neutronic considerations, and is at present about 730 g yr−1, much less than planned. The TVA has, however, received a license amendment to increase production to about 1.2 kg yr−1 in a single reactor [38]. It is not yet clear if there will be any unused capacity.

Operating a reactor in a tritium-producing mode requires more fresh fuel to produce the design power level. The amount of additional spent fuel seems to be a strongly non-linear function of the number of TPBARs loaded. The number of fresh fuel assemblies required per cycle will increase from 85 to 92 when the number of TPBARs is increased from 704 to 1792 [38]. Irradiation of 2500 TPBARs in a single reactor would increase spent nuclear fuel generation by about 24% in each fuel cycle [39], while if maximum tritium production is needed, up to 3400 TPBARs would be used and spent fuel generation would increase approximately 100%.

The EPR (a modern PWR design) does use burnable absorber rods, but in these the absorber is mixed with uranium dioxide. Replacement of these by lithium-containing rods with no uranium would impair the flat reactivity profile. The fuel burn-up would be reduced, and there might be other undesirable consequences. The AP1000 reactor has a more favourable design, as it uses both discrete burnable absorber rods (with no fuel) and integral fuel burnable absorber rods (with both fuel and boron). For example, in the first fuel cycle, the core would contain 8832 integral burnable absorbers, but only 1558 discrete absorber rods.

Fission power plants, PWRs in particular, each generate several tens of mg of tritium per year in the fuel, and somewhat more due to the use of depleted lithium in the coolant. The PWR industry has been looking at tritium extraction as a potential solution, but at the moment the process is about 100 times more expensive than discharge into the environment [40].

7. Proliferation

Tritium production or extraction facilities anywhere in the world create the risk that tritium could be diverted for military purposes. The quantity in one boosted bomb is 4 g or less, so diversion of a gram or two could have grave consequences. Boosted bombs can be more powerful but also smaller than fission bombs, making them more suitable for use in missile warheads. For example, the Swan device had a yield of 15 kilotons, with a diameter of only 30 cm [41].

The proliferation risks of fusion energy have been studied [42], but attention has focussed on whether fissile materials could be generated, since tritium itself does not provide access to nuclear weapons capability. In [43] the risk of diversion of tritium is relegated to a footnote. International control of tritium has been proposed [44], but at present neither tritium nor lithium-6 are regulated under the IAEA Safeguards regime. The risk of diversion would nevertheless be a major concern.

8. Discussion and conclusions

There are likely to be serious problems with supplying tritium for future fusion reactors. The tritium required for ITER (12.3 kg) will be supplied from the CANDU production in Ontario, but following this Ontario will probably be able to provide 8 kg only up to 2055 in scenario B, and 16 kg in scenario C. (These estimates are on the optimistic side, because there are many risks—reactors could be shut, etc.) If ITER and fusion development are successful, then two or three countries may build their own reactors, giving another major source of uncertainty in tritium requirements.

If Canada, the Republic of Korea, and Romania make their HWR tritium inventories available to the fusion community, there is a reasonable chance that 10 kg of T would be available for fusion R&D in 2055. Stocks would likely have to be shared if more than one fusion reactor is built.

It is worth noting that if scheduled HWRs refurbishments do not go ahead, or for some reason HWRs begin to be phased out earlier than expected across the globe, this would result in almost no tritium being available for fusion experiments. In Scenario A, and after the exploitation of ITER, OPG runs out of tritium in 2049. Alternative methods of production may be required if a fusion power reactor is built.

CANDU and similar heavy water reactors could in theory generate additional tritium in a number of ways: (a) adjuster rods containing lithium could be used; (b) a fuel bundle with a burnable absorber has been designed for CANDU reactors, uranium, which might be adapted for tritium production; (c) doping the moderator with lithium-6. For both light and heavy water reactors, governments and licensing authorities would be extremely reluctant to authorise new activities not required for electricity production.

It is in theory possible to start up a fusion reactor with little or no tritium, but at an estimated cost of $2 billion per kilogram of tritium saved, it is not economically sensible.

Minimising the tritium inventory should be a key design goal for any fusion reactor. This will require improvements in the fuelling efficiency and burn-up fraction, and reduction of the inventory in the plasma exhaust processing systems. While estimates suggest that the inventory in the blanket itself would be small, experimental research to confirm this is also important.

Acknowledgments

We would like to thank Alfred Mo, Neill Taylor, Scott Willms, Shanliang Zheng, Barry Butler, Damian King, Hugh Boniface, and Blair Bromley. This work has been carried out within the framework of the EUROfusion Consortium and has received funding from the Euratom research and training programme 2014–2018 under grant agreement No 633053 and from the RCUK Energy Programme (grant number EP/P012450/1). The views and opinions expressed herein do not necessarily reflect those of the European Commission. To obtain further information on the data and models underlying this paper, please contact the authors or PublicationsManager@ccfe.ac.uk.