Abstract

The lattice parameter changes in three types of Nb3Sn superconducting wires during uniaxial stress–strain measurements at 4.2 K have been measured by high-energy synchrotron x-ray diffraction. The nearly-stress-free Nb3Sn lattice parameter has been determined using extracted filaments, and the elastic strain in the axial and transverse wire directions in the different wire phases has been calculated. The mechanical properties of the PIT and RRP wire are mainly determined by the properties of Nb3Sn and unreacted Nb. This is in contrast to the bronze route wire, where the matrix can carry substantial loads. In straight wires the axial Nb3Sn pre-strain is strongest in the bronze route wire, its value being smaller in the PIT and RRP wires. A strong reduction of the non-Cu elastic modulus of about 30% is observed during cool-down from ambient temperature to 4.2 K. The Nb3Sn Poisson ratio at 4.2 K measured in the untwisted bronze route wire is 0.35. The present study also shows that the process route has a strong influence on the Nb3Sn texture.

Export citation and abstract BibTeX RIS

1. Introduction

The degradation of the critical current density (Jc) of Nb3Sn superconductors under mechanical loading due to Lorentz forces is a concern for the application of Nb3Sn cables in high-field magnets, such as those developed for instance for the planned high-luminosity upgrade of the large Hadron collider at CERN [1, 2]. The reversible strain dependence [3–8] of Jc is commonly ascribed to elastic Nb3Sn lattice distortions. Crack formation in the Nb3Sn filaments causes an irreversible Jc degradation, which does not recover when the load is released [9].

Previous lattice parameter measurements under tensile stress have been performed on tapes where the outer sheath was partially or completely removed, by using a laboratory x-ray diffractometer in the reflection geometry [10, 11]. However, since the penetration depth of 8.04 keV Cu Kα x-rays provided by a laboratory diffractometer is not sufficient to reach the Nb3Sn filaments of Nb3Sn/Cu wires, non-destructive studies of wires are not possible.

We have performed the first diffraction experiments on a single PIT wire under uniaxial tensile loading using neutrons, which can easily penetrate Nb3Sn wires [12]. These measurements allowed us to measure the lattice parameters of the different phases in the axial wire direction and perpendicular to it, and to obtain insights into the change of the structural behaviour of the composite wire during the heat treatment reaction when Nb3Sn forms and the Cu matrix is annealed. The neutron diffraction results also revealed a preferential Nb3Sn〈110〉 grain orientation in the PIT wire. However, the main drawback of the neutron diffraction experiment was the long acquisition time, of the order of hours, needed to obtain a diffraction pattern for a single wire in a given stress state. Neutron diffraction experiments are particularly useful for characterizing Nb3Sn wires or cables, such as the ITER conductor, involving a large sample volume and where the neutron penetration depth is mandatory [13, 14].

In contrast to neutron sources, state-of-the-art high-energy synchrotron beamlines such as ID15 at the European Synchrotron Radiation Facility (ESRF) provide a very high flux of high-energy x-rays, which exceeds the neutron flux of the most powerful neutron sources by many orders of magnitude. This enables the acquisition of diffraction patterns of Nb3Sn wires with excellent signal to noise ratios within seconds [15].

In the present article we report the evolution of elastic strain in the axial and transverse directions upon a tensile load applied in the various crystallographic phases of the three Nb3Sn strand types (bronze route (BR), restacked rod process (RRP) and powder-in-tube (PIT)), based on high-energy synchrotron x-ray diffraction (XRD) measurements.

To perform lattice parameter measurements during tensile tests at the superconductor operating temperature of 4.2 K with simultaneous extensometer wire strain measurements, a collaboration with the University of Geneva was started, with the latter providing the tensile rig and an x-ray transparent glass cryostat to be incorporated in the ID15B beamline set-up [16]. The nearly-stress-free Nb3Sn lattice parameter has been determined by temperature-dependent XRD measurements using 'powder' extracted from Nb3Sn filaments. The texture of Nb3Sn has been studied by high-energy synchrotron XRD and electron backscatter diffraction (EBSD).

2. Experimental details

2.1. The samples

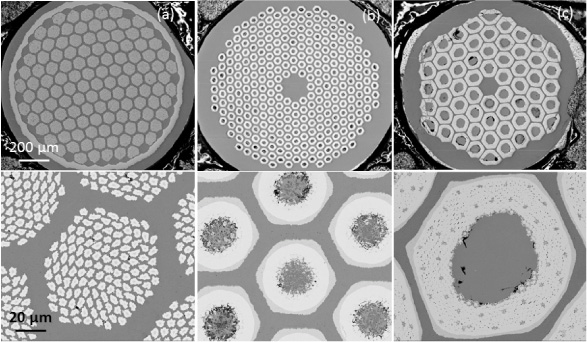

Figure 1 presents cross sections of the BR strand produced by the University of Geneva, the PIT strand produced by Shape Metal Innovation (now Bruker EAS) and the RRP strand produced by Oxford Instruments Superconducting Technology. The final heat treatment plateaus that have been applied for the reaction of straight 12 cm-long wires are 600 °C (100 h) + 670 °C (150 h), 650 °C (120 h) and 665 °C (75 h) for the BR, PIT and RRP wires, respectively.

Figure 1. Cross sections of the reacted (a) bronze route #26, (b) PIT B215 and (c) RRP #8056 (SEM images courtesy B Bartova, CERN).

Download figure:

Standard image High-resolution imageThe main wire characteristics are summarized in table 1. The Cu to non-Cu volume ratios are nominal values before the heat treatment reaction. During the heat treatment values before the heat treatment reaction. During the heat treatment reaction the wire cross sections and the non-Cu volume increase, mainly due to the formation of porosity, while the wire length changes only slightly [17]. The non-Cu cross sections have been calculated by assuming that the volume increase occurs only in the non-Cu part.

Table 1. Characteristics of the Nb3Sn wires (*nominal values before HT).

| BR #26 | PIT B215 | RRP #8056 | |

|---|---|---|---|

| Diameter after HT (mm) | 1.26 (1.25*) | 1.28 (1.25*) | 1.13 (1.10*) |

| Total cross section (mm2) | 1.25 | 1.29 | 1.00 |

| Cu to non-Cu vol. ratio* | 0.25 | 1.21 | 0.64 |

| Number of filaments | 14641 | 288 | 60 |

| Filament twist pitch (mm) | non | 20 | 12 |

2.2. In situ synchrotron x-ray diffraction

Synchrotron x-ray diffraction measurements were carried out at the ID15B high-energy scattering beamline of the European Synchrotron Radiation Facility (ESRF), using a 87.50 keV monochromatic x-ray beam with a bandwidth of 90 eV. The x-ray beam had a cross section of 0.1 mm × 0.1 mm.

Diffraction patterns were acquired with a Trixell Pixium 4700 two-dimensional flat-panel digital detector, with a sample to detector distance of 817 mm. Two-dimensional diffraction patterns were dissected into 32 circular sectors and then each sector was radially integrated, in order to measure lattice parameters from the crystalline planes oriented both perpendicular and parallel to the applied load; in the following these are referred to as the axial and transverse directions respectively.

Seven Nb3Sn, three Nb and two Cu reflections in the d-spacing range 1.3–2.7 Å have been recorded simultaneously. Diffraction peak positions were determined after fitting individual diffraction peaks with pseudo-Voigt functions over a linearly sloped background. Lattice strains were calculated from d-spacing changes of multiple peaks. More details about the diffraction experiments can be found in [16]. Ta alloying and slight alloying with Ti changes the Nb lattice parameter only marginally, and in the following we refer to Nb, regardless of whether the Nb is alloyed with Ta or Ti.

The tensile rig for the measurement of tensile stress–strain curves in liquid He was fitted into an x-ray transparent glass cryostat that could be placed in the x-ray beam of the ESRF ID15B beam line. All experiments were performed with the samples completely immersed in liquid He at atmospheric pressure.

3. Results

3.1. Texture in the different constituents inside Nb3Sn wires

The texturing of the strand constituents as a result of the wire drawing and heat treatment processes, causes an elastic anisotropy that needs to be taken into account when estimating the stress in the wire constituents from the elastic strain. Cu develops a duplex texture with a major 〈111〉 component, and Nb has a strong 〈110〉 texture, typical for strongly cold drawn bcc metals [12].

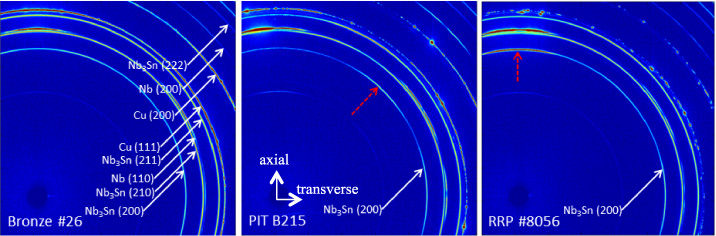

The Nb3Sn texturing depends strongly on the process route. In particular the Nb3Sn texture in RRP-type and PIT-type conductors differs markedly, as can be seen in the diffraction patterns shown in figure 2. The Nb3Sn diffraction rings of the BR wire (e.g. Nb3Sn (200)) do not exhibit strong intensity fluctuations, indicating a nearly random crystallite orientation in this wire [18]. In contrast, systematic intensity variations in the 2D diffraction patterns of both PIT and RRP wires show that in these wires a preferential Nb3Sn grain orientation exists. In the diffraction patterns the intensity maxima occur at different positions, indicating that the texture in RRP and PIT wires differs. Indeed, by EBSD measurements we have shown that in PIT-type and RRP-type wires Nb3Sn has a 〈110〉 and 〈100〉 texture, respectively [19], consistent with the x-ray measurements.

Figure 2. Diffraction pattern acquired for the BR #26, PIT B215 and RRP #8056 wires. The dashed arrows indicate the positions of intensity maxima in the Nb3Sn (200) rings.

Download figure:

Standard image High-resolution image3.2. The nearly-stress-free lattice parameter and axial pre-compression of Nb3Sn

The Nb3Sn phase in multifilament composites is under axial pre-compression, due to mismatch of the thermal expansion coefficients of the different wire constituents. It is commonly assumed that the maximum critical current density is obtained when the second deviatoric invariant of the strain tensor is zero [4]. This is only achieved when applying a certain tensile strain at which the Nb3Sn lattice parameters in the axial and transverse direction are approximately the same, i.e. the stress is uniform.

The nearly-stress-free Nb3Sn lattice parameter in the PIT B215 wire has been determined at the NHMFL with a Huber Guinier 670 diffractometer equipped with a helium cold stage, using 'powder' produced from filaments that were extracted from the fully processed PIT B215 wire. At 10 K the nearly-stress-free Nb3Sn lattice parameter was 5.275 Å. This is an average value for the Nb3Sn in the PIT wire, which is not homogeneous, a Sn concentration gradient being present in PIT wires [20]. For comparison, Nb3Sn extracted from a BR wire has a reported value of a = 5.276 Å at 7 K [21].

The Nb3Sn lattice parameters in extracted filaments differ only slightly from the Nb3Sn lattice parameters in the wires when the axial and transverse lattice parameters are equal (see table 2), and it can be assumed that the nearly-stress-free lattice parameters at 4.2 K in the three wires studied vary between 5.275 and 5.277 Å. Therefore, in the following, all elastic strain values are calculated with respect to the lattice parameter at which axial and transverse lattice parameters are equal. The approximate axial Nb3Sn pre-strain values shown in table 2 correspond to the axial Nb3Sn lattice variation after which the axial and transverse lattice parameters are equal. The Nb lattice parameters at 4.2 K where the axial and transverse values are equal were found to vary between 3.292 and 3.295 Å for the various wires.

Table 2. Nb3Sn and Nb nearly-stress-free lattice parameters at 4.2 K, estimated from the crossing of the axial and transverse lattice parameters and approximate Nb3Sn axial lattice pre-strain.

| Sample | Nb3Sn axial = Nb3Sn trans (Å) | Nb3Sn axial pre-compression (%) | Nb axial = Nb trans (Å) |

|---|---|---|---|

| RRP #8056 | 5.276 | 0.03 | 3.294 |

| BR #26 | 5.275 | 0.2 | 3.292 |

| PIT B215 | 5.277 | 0.02 | 3.295 |

As expected, the strongest Nb3Sn axial pre-compression, of about 0.2%, is found in the BR wire (see table 2). For comparison, the strain εmax at which the maximum critical current is obtained when straining similar bronze route wires with a Walters spring is typically between 0.2 and 0.3% [22].

The axial Nb3Sn pre-compression in the straight PIT B215 wire is significantly smaller than the εmax value reported for the same wire as measured by means of a Walters spring [23]. For another Nb3Sn PIT wire an εmax value similar to the value measured in this work is reported [24].

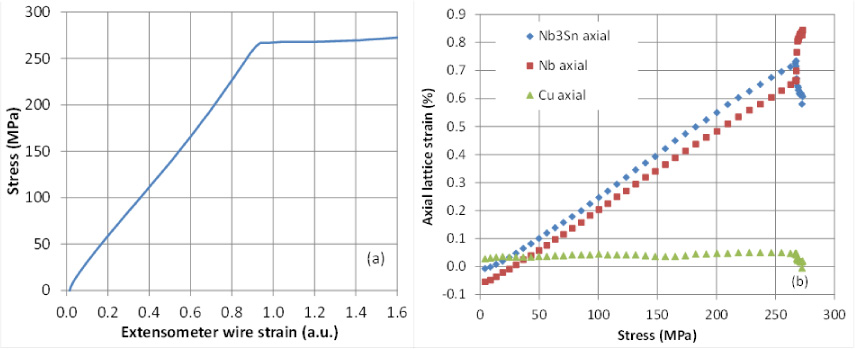

3.3. Mechanical wire properties

A stress–strain curve acquired for the PIT B215 wire in liquid He at 4.2 K is shown in figure 3(a). The Nb3Sn, Nb and Cu lattice strains in the axial direction, as determined from the simultaneously recorded diffraction pattern, are shown in figure 3(b). After an initial increase of the wire stress with increasing strain, a plateau is reached at about 270 MPa. Further straining the wire changes the wire stress only slightly. In figure 3(b) it can be seen that the Nb3Sn and Nb lattice parameters increase almost linearly with increasing stress until about 0.7% strain, where the Nb3Sn filaments break, which is detected by a relaxation and a decrease of the Nb3Sn lattice parameter. At the same time the load is transferred from the Nb3Sn to the Nb, which causes a higher stress in the Nb barrier, as seen by an increased axial Nb lattice parameter. The Cu lattice parameter remains nearly constant during the tensile test, showing that the annealed Cu matrix deforms plastically, even at very low loads, and cannot carry substantial loads.

Figure 3. PIT B215 engineering stress–strain curve measured at 4.2 K (a) and axial lattice strain in the different PIT B215 wire phases measured simultaneously by x-ray diffraction as a function of wire stress (b). The assumed Nb3Sn, Nb and Cu stress-free lattice parameters are 5.277 Å, 3.295 Å and 3.604 Å, respectively.

Download figure:

Standard image High-resolution imageThe onset of irreversible degradation of the Nb3Sn superconducting properties in the PIT wire at a strain below 0.4% [23] is not revealed by the lattice parameter measurements.

In figure 4(a) the wire stress is plotted as a function of the axial Nb3Sn lattice strain in the three different wires at 4.2 K, clearly showing the better mechanical properties of the BR wire as compared to the RRP and PIT wires. Like in the PIT wire, in the RRP wire the annealed Cu stabilizer yields plastically and does not carry substantial loads, and the Nb3Sn axial lattice parameter increases linearly with the wire stress. This is in contrast to the BR wire, where the bronze matrix initially shows a partly elastic behaviour. When the stress in the BR wire exceeds about 100 MPa the bronze matrix yields plastically and the load initially carried by the matrix is transferred to Nb3Sn and the unreacted Nb, which both exhibit a linear elastic behaviour in the entire stress range relevant for superconducting wire applications. The fact that the BR wire stress increases to higher values than that of the PIT and RRP wires is also partially due to the very low Cu to non-Cu ratio of the BR wire studied here (see table 1).

Figure 4. (a) Comparison of the stress in the BR, RRP and PIT wire as a function of the Nb3Sn axial lattice strain at 4.2 K (normalized to the nominal wire cross section). (b) Comparison of the stress in the PIT wire at RT and at 4.2 K (normalized to the non-Cu cross section).

Download figure:

Standard image High-resolution imageIn figure 4(b) the stress normalized to the non-Cu part of the PIT wire is plotted as a function of the Nb3Sn axial lattice strain at RT and at 4.2 K. Assuming iso-strain conditions and that the entire load is carried by the non-Cu part of the PIT wire, an effective non-Cu E-modulus of 73 GPa in the axial wire direction can be estimated at 4.2 K. The RT non-Cu E-modulus estimated in the same way is 99 GPa, confirming a strong Nb3Sn lattice softening during cool-down from RT to 4.2 K [25]. Since the E-modulus of the unreacted Nb increases at lower temperatures [26], it can be concluded that the E-modulus of the ternary Nb3Sn in the PIT wire decreases during cool-down from 290 to 4.2 K by more than 26%. For the RRP wire the non-Cu E-modulus (normalized to the cross section of Nb3Sn, unreacted Nb and the filament core) decreases by 30% during cool-down from RT to 4.2 K.

3.4. Nb3Sn Poisson ratio

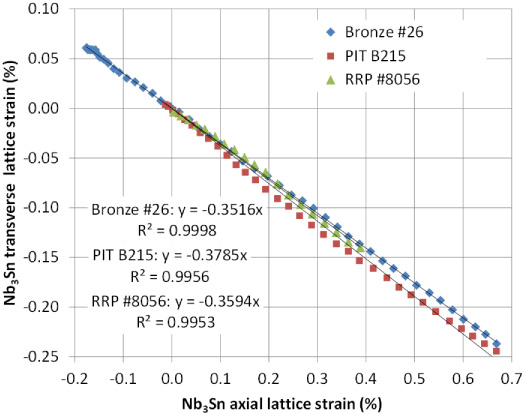

The effective Nb3Sn Poisson ratio at 4.2 K in the different wires is determined as the ratio of the axial and transverse lattice parameter changes. In figure 5 the elastic Nb3Sn strain in the transverse direction as a function of the axial Nb3Sn strain is compared for the BR, RRP and PIT wires. In the case of the BR and RRP wires the results shown are the average of all recorded reflections. The small intensity of the (200) reflection for the PIT wire indicates that a small amount of [100] texture is also present, but can be considered a minor constituent and has not been taken into account in the determination of the effective Nb3Sn Poisson ratio.

Figure 5. Transverse Nb3Sn strain as a function of axial Nb3Sn strain at 4.2 K in the BR, RRP and PIT wires. Lattice strains are calculated by assuming nearly-stress-free Nb3Sn lattice parameters of 5.276 Å, 5.275 Å and 5.277 Å in the RRP, BR and PIT wires, respectively. These values may deviate somewhat from the stress-free Nb3Sn lattice parameters in a perfect powder.

Download figure:

Standard image High-resolution imageThe Nb3Sn lattice strains in the axial and transverse directions are shown with respect to the nearly-stress-free Nb3Sn lattice parameter (see table 2). The effective Nb3Sn Poisson ratios from these slopes are 0.35, 0.36 and 0.38 for the BR, RRP and PIT wires, respectively.

A particularly good correlation between transverse and axial strain is obtained for the untwisted BR wire. It shows how well the entire experiment, including sample and detector alignment in the liquid helium, calibration of the energy and detector distance, as well as peak fitting have worked. The low noise in the diffractograms due to the high x-ray flux and the fact that that seven hkl could be recorded and analyzed at the same time further contributes to the quality of the XRD results presented here.

4. Discussion and conclusion

The Nb3Sn, Nb and Cu lattice parameter changes in the axial and transverse wire directions were measured by high-energy synchrotron x-ray diffraction in situ during stress–strain measurements.

As can be seen in figures 3 and 4, in the PIT and RRP wire at 4.2 K the mechanical properties are determined by the properties of Nb3Sn and unreacted Nb. Only in the BR wire can the matrix initially carry substantial loads.

The comparison of the non-Cu E-moduli at RT and at 4.2 K indicates that the combined Nb3Sn and unreacted Nb E-modulus in the axial direction decreases by about 30% during the cool-down to 4.2 K.

In the PIT wire, filament fracture and a simultaneous load transfer to the unreacted Nb is observed at an axial Nb3Sn strain of about 0.7%. The expected onset of irreversible degradation at lower strains, due to formation of first cracks in the Nb3Sn filaments, is not detected by the lattice parameter measurements. A more detailed diffraction peak width and shape analysis could possibly reveal early crack formation, provided that the instrument function is small compared to peak width changes caused by the inhomogeneous stress distribution [27]. The relatively small sample volume probed by XRD may also be a reason why transport current measurements using long wires are more sensitive at detecting irreversible Nb3Sn degradation.

The nearly-stress-free 'average' Nb3Sn lattice parameter in the PIT B215 strand at 4.2 K is 5.275 Å. Similar values are obtained for Nb3Sn in the PIT B215, RRP #8056 and BR #26 wires at the point where the axial and transverse lattice parameters are identical.

Due to a residual thermal strain in the composite wires, the Nb3Sn and Nb components are under compression, whereas the Cu and the bronze components are under tension. The wire design has a strong influence on the magnitude of these strains. The axial Nb3Sn pre-strain is strongest in the BR wire, and relatively small in the PIT and RRP wires. This can be explained by the relatively high stress that can be transferred by the bronze matrix. The differences between the Nb3Sn pre-strain values found in this work and those derived from Ic versus strain measurements, for instance, by using Walters springs, may be partly explained by the influence of the sample geometry on the Nb3Sn stress state inside the composite. As an example, the axial and transverse Nb3Sn lattice parameters measured by neutron diffraction in a PIT B215 wire mounted and reacted on a Ti–V–Al critical current measurement barrel at 10 K are 5.272 Å and 5.283 Å, respectively [28]. The corresponding lattice parameters measured in the straight wire by synchrotron XRD are 5.276 Å and 5.278 Å, respectively. Thermal cycling [28] and wire bending [29] can further influence the Nb3Sn stress state.

The effective Poisson ratios determined from transverse to axial Nb3Sn strain ratios at 4.2 K vary between 0.35 and 0.38 in the three wires studied. For the RRP and PIT wires the results may be slightly influenced by the wire twist pitch, the influence of which is small [30]. The different Sn gradients present in the different wire types may also slightly influence the mechanical properties. The transverse versus axial lattice curves pass through the zero-point when calculating lattice strain with the assumed values for strain-free Nb3Sn of 5.276 Å for the RRP wire, 5.275 Å for the BR wire and 5.277 Å for the PIT wire (see table 2). For the purpose of determining the Poisson ratio we think it is justified to use these values, since for Nb3Sn extracted from the PIT wire a similar lattice parameter of 5.277 Å is found. An effective Nb3Sn Poisson ratio at 4.2 K of 0.38 in another twisted RRP wire has been reported elsewhere [31], consistent with our results.

The process route has a strong influence on the preferential Nb3Sn grain orientation in multifilamentary composite wires. In the PIT wire the 〈110〉 drawing texture of the Nb precursor is preserved in the Nb3Sn, while in the RRP wire Nb3Sn grows mainly with a 〈100〉 direction in the wire-drawing direction. The homogeneous Nb3Sn diffraction pattern of the BR wire presented in figure 2 shows no strong Nb3Sn texture. The different Nb3Sn texture may partly explain a reversible Jc strain sensitivity dependence with respect to the process route, since uniaxial loading will cause a different distortion of the Nb3Sn lattice (mainly tetragonal in the RRP wire and mainly orthorhombic in the PIT wire). The preferential grain orientation may also have an influence on the irreversible strain limit.

In future experiments it would be advantageous to measure the superconducting properties and lattice distortions simultaneously on a single wire. This would allow a direct comparison of the changes of the lattice parameter and the superconducting properties, eliminating the influence of sample geometry, sample inhomogeneities, previous sample manipulation, thermal history and extensometer strain measurements.

Acknowledgments

We are grateful to A Ferreira, R Modoux, D Zurmuehle and A Schweizer from the University of Geneva for their technical assistance. We also would like to thank B Bartova from CERN for the electron microscopy images of the sample cross sections and Professor R Cerny of the University of Geneva for suggestions and fruitful discussions. The RRP wire #8056 was kindly provided by J Parrel of OST. TS and TB acknowledge support by the US Department of Energy, Office of Basic Energy Sciences under contract DE-SC0008832, and by the NHMFL, which is supported in part by the National Science Foundation Cooperative Agreement DMR-1157490, the State of Florida, the US Department of Energy, and Florida State University. We acknowledge the ESRF for beam time on ID15B.