Abstract

A multi-logic gate platform was designed based on morphological changes of gold nanorods (AuNRs) resulted from the iodine-mediated etching. By utilizing the anti-etching effects of mercapto compounds and Au-Hg amalgams as well as the etch-promoting effect of Cu2+, we successfully built five logic gates, namely, AND, NOR, XNOR, YES and IMPLY, along with a three-input combinational logic gate XNOR-IMPLY. The platform was versatile and easy to use, did not require complex surface modification or separation/purification steps as the conventional AuNR-based logic gates did. The logic operations, accompanied by distinct color changes, enabled multi-task detection by naked-eye for 'have' or 'none' discrimination or highly sensitive and selective analysis by spectroscopy with wide linear ranges.

Export citation and abstract BibTeX RIS

1. Introduction

Over the past several decades, gold nanomaterials have gained specific attention due to the strong localized surface plasmon resonance (LSPR) extinction in the visible-light region and the color conversions induced by changes in morphology, size or interparticle distance [1–6]. A number of colorimetric logic gates have been developed to date based on the aggregation-induced color changes of gold nanoparticles (AuNPs) [7–10]. Compared with the conventional fluorescent molecular logic gates, these AuNP platforms circumvent the drawbacks of the time-consuming and complicated modification of the molecules [11, 12] and the need for sophisticated equipment to read the fluorescence signals [13, 14]. However, AuNP-based logic gate platforms often need multiple separation or purification steps [9, 15]. In addition, the aggregation-based methods tend to suffer from autoaggregation in complex matrices, which sometimes cause high backgrounds and even false positive results [16, 17].

Gold nanorods (AuNRs) are elongated nanoparticles possessing two LSPR peaks attributed to the transverse (T-LSPR) and longitudinal (L-LSPR) bands [18]. The T-LSPR band is located at just above 500 nm while the wavelength of L-LSPR is longer, varying widely according to the aspect ratio (length-to-breadth ratio) and the overall size of the AuNRs [19]. Recently, AuNRs were employed as building blocks for logic gates. Yao et al [20] built a logic platform based on AuNPs and AuNRs that were functionalized with DNAs. By utilizing the sequence design technique, the DNA-AuNP and DNA-AuNR complexes were mediated to form geometrical assembly, and the outputs were characterized based on the two non-overlapping double hump-like UV–vis spectral peaks, i.e. the LSPR from AuNPs and the L-LSPR from AuNRs. Pallares et al [21] developed a plasmonic hybrid system made of AuNR and estrogen receptor element (ERE)-containing dsDNA. The AuNR aggregation triggered by the interprotein interactions among ERs (i.e. ERα and ERβ) was exploited to distinguish protein isomorphs.

The AuNR aspect ratio can be changed through etching [22]. In the presence of hydrogen peroxide, iodide ion could be oxidized to iodine, a moderate oxidant that was capable of etching cetyltrimethylammonium bromide-stabilized AuNRs along the longitudinal direction [23]. As a result, the L-LSPR band of AuNRs underwent blue-shift.

Inspired by these reports, we herein build a new AuNR-based plasmonic multi-logic gate platform, in which the logic inputs regulate the etching-induced morphological changes of AuNRs. The logic gate readouts can be utilized to explore reactions related to the etching process. Moreover, based on the color changes of AuNRs, the naked-eye logic detection simplifies the determination of analytes in samples to 'have' or 'none'. To the best of our knowledge, this is the first report constructing logic gates on the basis of changes of the AuNR morphology. The logic gate platform is easy to use and cost-effective; no complex handling procedures or expensive biomolecules like DNAs or enzymes are required. Besides, wide linear response ranges can be achieved with spectroscopic detection because variations in the AuNR aspect ratio lead to a broad-range change of L-LSPR signal in terms of wavelength [24]. The research expands the application scope of AuNR logic gate platforms from biomolecules to small organic molecules and even inorganic ions.

2. Methods

2.1. Chemicals and materials

Hydrogen tetrachloroaurate (III) trihydrate and cetyltrimethylammonium bromide (CTAB) were purchased from Sinopharm Chemical Reagent (Shanghai, China). L-ascorbic acid, sodium borohydride (NaBH4) and silver nitrate (AgNO3) were supplied by Alfa Aesar (Shanghai, China). Sodium iodide (NaI), mercury nitrate [Hg(NO3)2], hydrogen peroxide (H2O2, 30%) and copper chloride (CuCl2) were products of the Beijing Chemical Plant (Beijing, China). 11-mercaptoundecanoic acid (MUA) was obtained from Energy Chemical (Shanghai, China), and (11-mercaptoundecyl)trimethylammonium (MTA) bromide was provided by Sigma (St. Louis, MO, USA). The reagents were of analytical grade and used as obtained without any further purification. All stock solutions were stored in a refrigerator at 4 °C. Working solutions were prepared by appropriate dilution of the stock solutions with triple-distilled water, and were filtered through 0.22 μM filters (Jiuding High Tech., Beijing, China) before use.

2.2. Synthesis and characterization of AuNRs

The AuNRs were prepared following an Ag-assisted seed-mediated method [25], with moderate modification. Scheme

Scheme 1. Experimental flowchart for synthesis of AuNRs.

Download figure:

Standard image High-resolution imageUV–vis spectra of the AuNPs were recorded on an UV-2450 UV–vis spectrophotometer (Shimadzu Corporation, Kyoto, Japan) using a 1 mm thickness quartz cuvette with 10 mm light pass. The morphology of the AuNRs was visualized on a TF20 (200 kV, FEI Tecnai, Oregon, USA) transmission electron microscope (TEM).

2.3. Construction of the logic gate

The etching solution (ES) was a freshly-prepared mixture of 200 mM H2O2, 0.4 mM NaI and 0.4 mM hydrochloric acid. The AuNRs were dispersed in 0.1 M CTAB. Unless otherwise stated, the base solution was 200 μl AuNR dispersion. The logic inputs included I−, H2O2, MTA, MUA, Hg2+ and Cu2+, which were added to the base solution to desired concentrations.

For logic operation, the base solution was transferred to a 0.5 ml centrifuge tube and placed in a water bath at 50 °C for 10 min Afterward, logic stimuli were introduced to the base solution, and the mixture was vigorously stirred for 1 min, then kept in the water bath to allow the logic input-regulated etching to take place. Ten minutes later, the mixture was cooled in an ice-water bath to terminate the etching process. The final solution was observed by naked-eye or measured by UV–vis spectroscopy.

2.4. Definition of the logic values

The logic values of the inputs 0 and 1 were defined as the absence and the presence of the inputs, respectively. For outputs observed by naked-eye, the wine red color of the AuNP colloids before etching was defined as 0, and the color of the etched AuNR solution displaying light blue was defined as 1. Because the degree of AuNR color change reflected the extent of etching, which could be quantitatively characterized by the wavelength shifting of the L-LSPR peak, a parameter named relative L-LSPR shift Rλ was adopted as the criterion:

where λmax and λ corresponded to the wavelengths of the L-LSPR peaks of the AuNRs before and after etching, respectively. Herein, the outputs 0 and 1 in UV–vis measurements were experimentally established as below Rλ = 0.005 and above Rλ = 0.24, respectively, so that the output signals from all logic gates are coherent.

3. Results and discussions

3.1. Mechanism for the logic gate system

The AuNRs prepared by the seed-mediated approach displayed a color of wine red. The UV–vis spectra depicted a strong L-LSPR band and a weak T-LSPR band near 840 and 520 nm, respectively (figure 1). The TEM image indicated that the AuNPs were about 40 nm in length and 10 nm in diameter (figure S1 is available online at stacks.iop.org/NANO/30/055503/mmedia), with an average aspect ratio of ca. 4. The tips of the nanorods were less-covered, because during the seed-mediated growth of AuNRs in the presence of CTAB as the shape-directing surfactant, CTAB preferentially bound to the {100} Au faces along the length of the rods, compared with the end {111} Au faces, owing to the size of the CTAB headgroup [26]. The exposed tips were eroded in the presence of the ES consisting H2O2 and I− [23]

Furthermore, it was proposed that presence of cetyltrimethylammonium ion (CTA+) favored the corrosion of AuNRs by the following reaction [27]

As a consequence, the AuNRs would gradually shrink along the longitudinal direction (figure 1, Panels (a), (b) and (c)), which was accompanied by a blue-shift in the L-LSPR band (figure 1(d)).

Figure 1. TEM images and naked-eye observations of the 200 μl AuNRs solution (A) after 10 min corrosion by mixing with 10 μl (B) and 20 μl (C) ES. Panel D depicts the corresponding UV–vis spectra.

Download figure:

Standard image High-resolution imageHowever, the etching is affected by some factors. For example, the exposed tips can be covered by mercapto compounds via chemisorption and, hence, the etching process is hindered [28, 29]. Moreover, as found by our experiment, the etching process can also be impeded by the formation of Au-Hg amalgam. On the other hand, the AuNR erosion process can be promoted by addition of some species, such as Cu2+, as a moderate oxidant. Therefore, by employing mercapto compounds (MTA and MUA), Hg2+, Cu2+, I− and H2O2 as inputs, numerous logic gates could be built.

3.2. Optimization of the platform parameters

To make the color change of AuNRs occur smoothly and repeatably, the conditions of the logic platform were optimized with regard to the dispersion medium of the AuNRs, the volume of the base solution, and the acidity and volume of the ES. The dispersion medium for the AuNR colloids played an important role in the color transition. The AuNRs washed by triple-distilled water two times and redispersed in 0.1 M CTAB offered the maximum blue-shift of the L-LSPR absorption (figure S2). The reason might be that CTA+ ion facilitated the etching process [27]. With regard to the volume of the base solution (AuNR solution), it was found that long etching time (>15 min) was required with 3 ml AuNR solution placed in a 5 ml centrifuge tube, probably due to the relatively poor heat transfer efficiency during etching. However, when the base solution volume decreased to 100 μl, it was difficult for the naked-eye discrimination of the color changes. A volume of 200 μl could fulfill the requirements for naked-eye observation and instrumental measurement, and save the precious AuNRs.

Hydrochloric acid was added to the ES to facilitate corrosion, because an acidic environment would improve the yield of iodine and coordination between Cl− and Au+ would reduce the electric potential of Au+/Au [30]. Under typical conditions, the ES contained 0.4 mM hydrochloric acid. Finally, the volume of ES was optimized. Under a fixed etching time of 10 min, mixing different volumes of ES with 200 μl AuNRs gave rise to varying final colors (figure 1). The final solution became brown upon the addition of 10 μl of ES. However, with addition of 20 μl ES, a light-blue solution was obtained, which was readily distinguishable from the original wine red. Therefore, the volume of ES was set to 20 μl. The optimal etching conditions were adopted throughout the work for the good performance.

3.3. The 'AND' logic gate stimulated by iodine-mediated etching

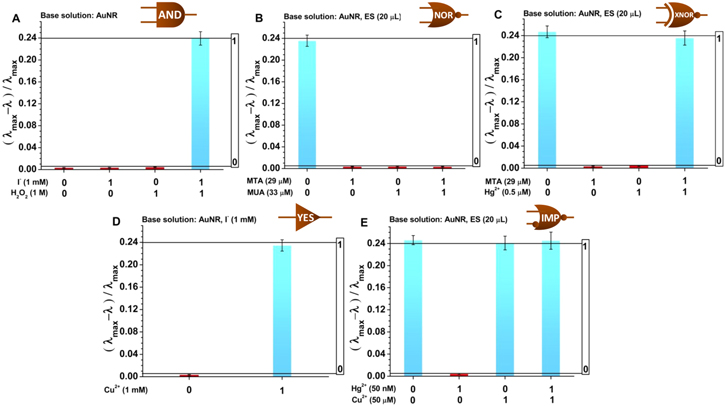

Presence of iodine is a prerequisite for the AuNR corrosion. We found that neither 1 mM I− (0/1) nor 1 M H2O2 (1/0) as the input could induce a color change, implying no etching took place. Only when the two inputs were simultaneously applied (1/1) did the color of the resultant solution change from wine red to light blue. Based on this phenomenon, an 'AND' logic gate was developed (figure 2(a)).

Figure 2. Relative L-LSPR shifts [(λmax − λ)/λmax] as a function of different inputs in the (A) AND; (B) NOR; (C) XNOR; (D) YES; (E) IMPLY logic gates. Data were processed based on three replicates.

Download figure:

Standard image High-resolution image3.4. Logic gates operated by anti-etching reagents as stimuli

Two mercapto compounds, MTA and MUA, were employed as inputs to build a 'NOR' logic gate (figure 2(b)) by utilizing their anti-etching effects. The tips of CTAB-stabilized AuNRs were more exposed compared with the sides, and were more vulnerable to etching reactions, leading to an anisotropic reshaping. However, the mercapto compounds introduced could attach to the tips via formation of Au-S bonds. The chemisorbed long-chain mercapto compounds formed a new layer on the AuNR tips, serving as a barrier hindering the etching process. The concentrations of MTA and MUA in the final solution were optimized to be 29 and 33 μM, respectively, by means of relative L-LSPR shifts (figures S3 and S4). Individual input (0/1 or 1/0) could prevent the corrosion of AuNRs. Upon simultaneous stimulation (1/1), however, a similar level of protection was obtained, rather than a higher one. The phenomena were ascribed to the fact that in the base solution, the number of binding sites provided by the AuNRs was less than the number of MTA or MUA molecules inputted. The binding sites were completely occupied upon introducing either of the mercapto compounds. The minimum input value was lower for MTA. Although the two mercapto compounds have same chain length, they are differentiated by the terminal groups. MTA is terminated with a quaternary ammonium group, which is water-soluble and hence more accessible to AuNRs in aqueous solution [31, 32]. However, the relatively poor water solubility of MUA restrained its chemisorption on the AuNRs [33].

It was reported that Hg2+ could deposit on the tips of the AuNRs by forming Au-Hg amalgams in the presence of a reducing agent [34]. In our experiment, ascorbic acid was employed in synthesizing the AuNRs, and the residual ascorbic acid, which physically adsorbed on the tips of AuNRs, might initiate the in situ reduction of Hg2+. We found that with increasing amount of Hg2+ added, the intensity of the L-LSPR peak decreased gradually, concomitant with a very slight, almost negligible, hypochromic shift (figure S5), suggesting the formation of Au-Hg amalgams on the AuNR surfaces [35]. Furthermore, in the presence of the Hg2+, the wavelength of the L-LSPR band virtually did not change with the introduction of ES (figure S6), implying that the Au-Hg amalgams on the AuNR tips hindered etching. According to the above results, an 'XNOR' gate was constructed using MTA and Hg2+ as stimuli (figure 2(c)). Introducing either MTA (29 μM) or Hg2+ (0.5 μM) prevented AuNR etching and, accordingly, the solution maintained its original wine red color. However, the AuNR colloids turned into light blue upon application of both inputs (1/1). At input (1/0), MTA chemisorbed on the AuNR tips via Au-S bond. In addition, because it had a linear structure, which was relatively flexible, MTA could bind to the rod side via ligand exchange [36]. Further, this linear mercapto compound might even bind all over the nanorod [26], making the positive charge density on the rod side higher than that on the ends. On the other hand, at input (0/1), Hg2+ would preferentially attach on the AuNR tip owing to the lower Coulombic repulsion at this region relative to the longitudinal side. The above mechanisms explain why much higher concentration of MTA (nearly 60 folds as Hg2+) was needed for the protection. Similarly, at input (1/1), Hg2+ selectively attached to the AuNR tips due to the relatively weaker electrostatic repulsion. Because the mercapto group has stronger affinity with Hg0 than with Au0 [37], the simultaneous detachment of anti-etching reagents MTA and Hg2+ from the AuNR tips was responsible for the morphological change.

3.5. Logic operations based on etch-promoting reagents

We found that presence of Cu2+ significantly promoted the etching. Therefore, a 'YES' logic switch was rationally developed (figure 2(d)), which was a 1-input 1-output gate performing logic affirmation. The base solution (mixture of 200 μl AuNRs and 20 μl 11 mM NaI) was wine red initially; it became light blue upon the addition of 1 mM Cu2+. The standard potential of the Cu2+/Cu+ redox couple [ (Cu2+/Cu+) = 0.17 V] is lower than that of I2/I− [

(Cu2+/Cu+) = 0.17 V] is lower than that of I2/I− [ (I2/I−) = 0.536 V] [38], suggesting that the reaction of equation (4) could not take place spontaneously.

(I2/I−) = 0.536 V] [38], suggesting that the reaction of equation (4) could not take place spontaneously.

However, formation of CuI precipitates will promote the reaction, such that oxidation of iodide by Cu2+ through equation (5) can proceed smoothly (refer to the supporting information is for detail), yielding iodine to facilitate AuNR etching.

Because Hg2+ and Cu2+ functioned oppositely on AuNR etching, we adopted the mechanisms and built an 'IMPLY' logic gate (figure 2(e)). The base solution consisted of 200 μl AuNRs and 20 μl ES. When the two inputs were 0 (0/0), the AuNRs were etched, displaying a color of light blue. Presence of 0.05 μM Hg2+ (1/0) inhibited the corrosion, whereas addition of 50 μM Cu2+ (0/1) accelerated the process. Notably, application of both inputs (1/1) led to a color change of the AuNR colloids from wine red to light blue. The in situ reduction of Hg2+ by the residual ascorbic acid produced a thin layer of Au-Hg amalgam covering the AuNR tips. The anti-etching effect of the amalgam layer was effective against the mild ES consisting H2O2 and I−, but was overwhelmed by the iodine-mediated etching synergetically boosted by H2O2 and Cu2+.

3.6. Construction of combinational logic gate

Since the output of one logic gate can be the input signal of another, combination of different logic gates through cascade reactions can lead to more intricate logic units. We utilized the mixture of 200 μl AuNRs and 20 μl ES as base solution. By carefully balancing the protection effect of MTA, the anti-etching effect of the Au-Hg amalgams and the oxidation effect of Cu2+, two basic binary logic gates XNOR and IMPLY were successfully integrated into a ternary combinational logic gate (figure 3), which worked with the stimuli of Cu2+, Hg2+ and MTA at concentrations of 50 μM, 0.5 μM and 29 μM, respectively. The different results from inputs (1/0/1) and (0/1/1) revealed the varying protection efficiencies of MTA and Hg2+. The anti-etching mechanism by MTA was based on formation of the Au-S bond, while the protection by Hg2+ relied on the formation of Au-Hg amalgams. With the input of (1/1/1), an output of 1 was obtained because the simultaneous presence of MTA and Hg2+ resulted in the detachment of the anti-etching agents by forming stable Hg2+-MTA complexes, whereas introducing Cu2+ accelerated the etching process. The combinational logic gate had eight input states and eight corresponding output signals, providing more complicated information related to the etching/protection reactions. Moreover, the three-input logic gate had the potential to function as a multi-task sensor, thereby fulfilling the colorimetric detection of multiple analytes.

Figure 3. Schematic illustration of the combinational XNOR-IMPLY logic gate constructed via cascade reactions. The outputs in the table are the observed results versus the three-input states. Base solution: 200 μl AuNRs and 20 μl ES. The concentrations of Cu2+, Hg2+ and MTA were 50 μM, 0.5 μM and 29 μM, respectively.

Download figure:

Standard image High-resolution image3.7. Statistical assessment of the logic gate outputs

All the outputs in terms of the relative L-LSPR shifts [(λmax − λ)/λmax] were successfully labeled as logic 0 or 1 since they were not significantly different from the reference values 0.005 and 0.24, respectively (p > 0.05, table S1). Meanwhile, the values for logic 0 were significantly different and easily distinguishable from the values for logic 1 (p < 0.05, table S2; Cohen's d > 21.5, table S3).

3.8. Potential for detection

Theoretically, a logic device is a platform for analysis. We selected the 'XNOR' logic gate as an example to study its applicability in detecting Hg2+. Hg2+ in the water body has drawn on-going concerns because the long-term accumulation of mercury in human body can cause immunological disorders, kidney damage and neurological diseases. We found that without resorting to sophisticated instruments, the limit of detection (LOD) for Hg2+ by naked-eye was 50 nM. Spectroscopic detection possessed higher sensitivity, offering LOD of 4.9 nM, which could be applied to detecting Hg2+ in drinking water that satisfied the US EPA guidelines (∼10 nM for Hg2+) [39]. Moreover, as altering the AuNR aspect ratio gave rise to optical signals in a wide range of wavelengths [24], this AuNR morphology change-based method provided wider linear ranges (Hg2+: 0.01 ∼ 0.5 μM, Rλ = 0.455× + 0.00438 (μM), r2 = 0.9930, see figure 4 and table 1) than the AuNP aggregation-based counterparts [40].

Figure 4. Detection of Hg2+ by the 'XNOR' gate. (A) Output UV–vis spectra upon inputs of 29 μM MTA and different concentrations of Hg2+ (μM): 1, 0.0; 2, 0.01; 3, 0.05; 4, 0.1; 5, 0.2; 6, 0.3; 7, 0.4; 8, 0.5; 9, 0.6; 10, 0.7. (B) Data processing for the raw data in panel A. The upper left inset shows the images of the final solutions, the concentrations of Hg2+ from left to right: 0.0—0.7 μM. The bottom right inset shows a linear relationship between Rλ and the concentration of Hg2+ (0.01–0.5 μM). The error bars are the standard deviation of the mean from three measurements. The base solution, 200 μl AuNR with aspect ratio 4 and 20 μl ES.

Download figure:

Standard image High-resolution imageTable 1. Detection of Hg2+ with AuNRs of different aspect ratios.

| Aspect ratio | Linear range (μM) | Regression equation | r2 | LOD (nM) |

|---|---|---|---|---|

| 3 | 0.04 ∼ 0.5 | Rλ = 0.339× + 0.0826 | 0.9983 | 6.5 |

| 4 | 0.01 ∼ 0.5 | Rλ = 0.455× + 0.00438 | 0.9930 | 4.9 |

| 5 | 0.01 ∼ 1.0 | Rλ = 0.236× + 0.0750 | 0.9770 | 9.3 |

As suggested by a reviewer, we studied the influence of AuNR aspect ratio on Rλ and LOD of Hg2+. To this end, we synthesized additional AuNRs with aspect ratios of ca. 3 and 5, with rod length/diameter (in nm) of 60/20 and 40/8, respectively (please refer to the supporting information for synthesis procedures and figures S7 and S8 for TEM images), and applied them in the detection of Hg2+. The LODs obtained with all the AuNRs satisfied the US EPA guidelines, but the AuNRs of aspect ratio 4 offered the most sensitive detection (table 1). The AuNR aspect ratio determined the wavelength of L-LSPR peak, which were 783, 840 and 891 nm for AuNRs with aspect ratios of ca. 3, 4, and 5, respectively (figures 4 and S9 and S10). In addition, according to equation (1), aspect ratio affected the Rλ value. This is also reflected by the experimental results; for example, in the presence of 0.4 μM Hg2+, the Rλs for the above AuNRs were 0.2181, 0.1909 and 0.1818, respectively. Furthermore, table 1 indicates that AuNRs with higher aspect ratio provided wider linear range, because their L-LSPR wavelength could be changed in a broader range during etching.

Selectivity of the logic detection was investigated by evaluating the relative L-LSPR shifts generated by the potential interfering ions. Our results (figure 5) indicates that presence of 0.5 μM Hg2+ generated a relative L-LSPR shift of 0.24, but the coexistence of other metal ions at a 100-fold excess could not give rise to a noticeable wavelength shift or color transition of the AuNRs. The logKf value of Hg(SCN)n is ca. 21.8, whereas the corresponding values for the SCN-complexes with Zn2+, Cd2+, Co2+, Ni2+, Mn2+, Pb2+, Fe2+, Cr3+, Cu2+, and Au+ are ca. 2.0, 2.8, 1.72, 1.76, 1.23, 1.48, 1.31, 3.08, 10.4, and 16.98, respectively [41]. The largest logKf value of Hg(SCN)n, which is nearly 20 orders higher than most of the interfering ions, endowed the 'XNOR' logic gate with high selectivity.

Figure 5. Relative L-LSPR shifts of the AuNR solution in the presence of 0.5 μM Hg2+ and 100-fold excess of other metal ions, including Cd2+, Co3+, Cr2+, Cu2+, Fe2+, Mn2+, Ni2+, Pb2+, and Zn2+. Data were processed based on three replicates.

Download figure:

Standard image High-resolution image4. Conclusions

A plasmonic logic gate platform was developed based on the morphological changes of gold nanorods induced by iodine-mediated etching. The molecular events occurring in aqueous solution could be translated into distinct color changes of the AuNR colloids, which could be observed by naked-eye or measured by UV–vis spectrometer. By employing MTA, MUA, I−, H2O2, Hg2+ and Cu2+ as inputs and exploiting the etching promotion/protection effects of these stimuli, we successfully built five different logic gates, viz., AND, NOR, XNOR, YES and IMPLY, along with a combinational three-input XNOR-IMPLY. These logic gates had the potential for complex computing as well as sensitive and selective detection with wide linear ranges. The platform is versatile, conceptually simple and easy to use. Compared with the conventional AuNR-based logic gates, the platform does not require complex surface modifications with expensive DNAs, RNAs or enzymes, or require separation/purification steps. To the best of our knowledge, this is the first report on building AuNR-based logic gates that exploit their morphological changes. By analogy, alternative building blocks, for example, gold-based multi-branched nanoparticles [42], nanobipyramids [43] and triangular nanoplates [44] for colorimetric readout, hypochlorite [45], chromium(VI)/bromide ion [46], enzymes [22] and thiosulfate system [47] as etchants, and mercapto compounds such as glutathione and captopril as anti-etching agents, can be employed to construct various plasmonic platforms based on this strategy to execute more logical operations.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (21575017) and the Fundamental Research Funds for the Central Universities.