Abstract

We demonstrated the grain size effect on piezoelectric properties of pure BaTiO3 ceramics. BaTiO3 ceramics with various grain sizes were prepared by conventional and two-step sintering methods. The piezoelectric strain constant d33 increased with decreasing grain size when the grain size was more than 1.2 µm, whereas it decreased when the grain size was below 1.2 µm. The maximum d33 was 460 pC/N, which is approximately three times larger than that of coarse BaTiO3 ceramics. The increase in d33 was well explained by the domain-wall contribution, while the decrease in d33 was understood as the grain boundary effect. On the other hand, the piezoelectric voltage constant g33 increased with decreasing grain size down to 0.6 µm. The piezoelectric constants d33 and g33, and the mechanical quality factor Qm can be controlled by the grain size of BaTiO3 ceramics.

Export citation and abstract BibTeX RIS

1. Introduction

Dielectric and ferroelectric properties of ferroelectric materials depend on grain size and film thickness, and this phenomenon is known as the "size effect" of ferroelectrics.1–12) For example, the grain size effect on the permittivity of BaTiO3 ceramics has been studied by many researchers because fine-grained ceramics with high permittivity have been required with the demands on the miniaturization and higher capacitance of multilayered ceramic capacitors (MLCCs). It was generally recognized that the permittivity of BaTiO3 ceramics increased with decreasing grain size at the micron level, whereas it decreased at the submicron level. On the other hand, the grain size effect on piezoelectric properties also attracts attention. An alternative of lead-based piezoelectric material is desired, and many researches have developed nontoxic lead-free materials with high piezoelectric properties. In addition to the control of chemical compositions, the control of microstructures such as domain configuration, grain orientation, and grain size, is also important to enhance the piezoelectric properties of lead-free materials. Recently, some researches have reported the grain size dependence of piezoelectric properties of BaTiO3 ceramics, in which the piezoelectric strain constant d33 increases with decreasing grain size.13–18) For the development of next-generation lead-free piezoelectric materials, it is necessary to understand the grain size effect on the piezoelectric properties of BaTiO3 ceramics and apply the knowledge to other materials. In this study, we prepared pure BaTiO3 ceramics with various grain sizes and estimated the grain size effect on piezoelectric properties of BaTiO3 ceramics.

2. Experimental procedure

BaTiO3 ceramics with various grain sizes were fabricated by conventional and rate-controlled two-step sintering methods.7,8,19–21) Hydrothermally synthesized BaTiO3 particles with an average size of 100 nm (Sakai Chemical BT-01) were used as the starting material. The BaTiO3 particles were isostatically pressed into discs at 200 MPa. In the conventional sintering method, green compacts were sintered at various temperatures of 1260–1380 °C for 2 h. In the rate-controlled two-step sintering method, green compacts were heated at 33 °C/min up to 1000 °C and 25 °C/min up to 1320 °C, and then immediately cooled at 30 °C/min to various lower temperatures of 1100–1320 °C and isothermally sintered for 10–15 h. The sintering conditions are described in detail elsewhere.7,8)

The density of the ceramics was measured by the Archimedes method. The grain size was measured by scanning electron microscopy (SEM; JEOL JSM-5310). The 90° domain configurations of the ceramics were observed by field emission scanning electron microscopy (FE-SEM; JEOL JSM-6301F) after the chemical etching of the sample surface in  solution for several tens of seconds.

solution for several tens of seconds.

The dielectric permittivity of the ceramics was measured using an impedance analyzer (Agilent 4294A) after forming Au electrodes on the two facing surfaces of ceramic plates. To measure the piezoelectric properties of the longitudinal vibration in the 33 mode, rectangular solid specimens of 1.5 × 1.5 × 3.75 mm3 were prepared. The specimens were poled in a silicone oil bath by applying the dc electric field of 1 kV/mm for 30 min at 80 °C. The piezoelectric strain constant d33, the piezoelectric voltage constant g33, the electromechanical coupling factor k33, the elastic compliance  and the free permittivity

and the free permittivity  were measured by a resonance–antiresonance method with IEEE standards using the impedance analyzer. Moreover, the electric-field-induced strain at 0.1 Hz was measured using a displacement meter (Mahr Millitron 1240).

were measured by a resonance–antiresonance method with IEEE standards using the impedance analyzer. Moreover, the electric-field-induced strain at 0.1 Hz was measured using a displacement meter (Mahr Millitron 1240).

3. Results and discussion

By conventional and two-step sintering methods, we obtained dense BaTiO3 ceramics with grain sizes of 0.6–12 µm. Details are shown in our previous papers.7–9) As reported in the previous papers, the dielectric permittivity depended on the grain size, i.e., the permittivity increased with decreasing grain size when the average grain size was more than 1.2 µm, whereas it decreased when the average grain size was below 1.2 µm (see Fig. 1). The maximum permittivity of the BaTiO3 ceramics was 8,000 for an average grain size of 1.2 µm. Note that the permittivity at a low frequency originates from the dipole and ionic polarizations, and therefore the permittivity depends on the measurement frequency.7,8) However, the trend of grain size dependence is the same in the frequency range from 1 to 1011 Hz.

Fig. 1. Grain size dependence of permittivity of BaTiO3 ceramics at 20 °C before poling treatment. The measurement frequency was 1 kHz.

Download figure:

Standard image High-resolution imageFigure 2 shows resonance–antiresonance curves originating from the piezoelectric response of the BaTiO3 ceramics with average grain sizes of 0.6, 1.2, and 2.4 µm at 20 °C. As shown in Fig. 2, the maximum of the phase of impedance was almost independent of grain size, suggesting that the degree of poling was almost constant regardless of grain size. When comparing the grain sizes of 0.6, 1.2, and 2.4 µm, the resonance and antiresonance frequencies were clearly varied, meaning that the electromechanical coupling factor k33 and the elastic compliance  depend on grain size. Figure 3 shows grain size dependences of piezoelectric properties at 20 °C. As shown in Fig. 3(a), the piezoelectric constant d33 increased with decreasing grain size when the grain size was more than 1.2 µm, whereas it decreased when the grain size was below 1.2 µm. The maximum d33 was 460 pC/N, which is approximately three times larger than that of coarse BaTiO3 ceramics, for an average grain size of 1.2 µm. The grain size dependence of d33 showed a tendency similar to that of the permittivity measured before and after the poling treatment [see Figs. 1 and 3(b)]. However, the grain size dependence of d33 was smaller than that of permittivity when the grain size was smaller than 1.2 µm. As shown in Figs. 3(c) and 3(d), the grain size dependences of the elastic compliance

depend on grain size. Figure 3 shows grain size dependences of piezoelectric properties at 20 °C. As shown in Fig. 3(a), the piezoelectric constant d33 increased with decreasing grain size when the grain size was more than 1.2 µm, whereas it decreased when the grain size was below 1.2 µm. The maximum d33 was 460 pC/N, which is approximately three times larger than that of coarse BaTiO3 ceramics, for an average grain size of 1.2 µm. The grain size dependence of d33 showed a tendency similar to that of the permittivity measured before and after the poling treatment [see Figs. 1 and 3(b)]. However, the grain size dependence of d33 was smaller than that of permittivity when the grain size was smaller than 1.2 µm. As shown in Figs. 3(c) and 3(d), the grain size dependences of the elastic compliance  and the electromechanical coupling factor k33 had similar tendencies to that of d33. A high k33 of more than 50% could be obtained with the grain size of 1.2 µm. Since d33 is expressed as

and the electromechanical coupling factor k33 had similar tendencies to that of d33. A high k33 of more than 50% could be obtained with the grain size of 1.2 µm. Since d33 is expressed as  , the grain size dependence of d33 was clearly due to the grain size dependences of k33,

, the grain size dependence of d33 was clearly due to the grain size dependences of k33,  , and

, and  . On the other hand, the piezoelectric voltage constant g33 increased with decreasing grain size down to 0.6 µm [see Fig. 3(e)]. This is due to the marked reduction in

. On the other hand, the piezoelectric voltage constant g33 increased with decreasing grain size down to 0.6 µm [see Fig. 3(e)]. This is due to the marked reduction in  compared with k33 and

compared with k33 and  . This result suggests that the grain size control is effective for increasing the g33, which is an important factor for piezoelectric sensor applications.

. This result suggests that the grain size control is effective for increasing the g33, which is an important factor for piezoelectric sensor applications.

Fig. 2. Resonance–antiresonance curves originating from piezoelectric response of the BaTiO3 ceramics with average grain sizes of (a) 2.4, (b) 1.2, and (c) 0.6 µm at 20 °C.

Download figure:

Standard image High-resolution imageFig. 3. Grain size dependences of piezoelectric properties [(a) d33, (b)  , (c)

, (c)  , (d) k33, and (e) g33] of BaTiO3 ceramics at 20 °C.

, (d) k33, and (e) g33] of BaTiO3 ceramics at 20 °C.

Download figure:

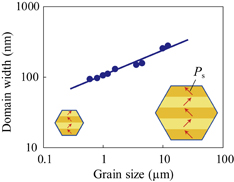

Standard image High-resolution imageThe increases in piezoelectric properties with decreasing grain size seemed to originate from the domain-wall contribution.7,8,18,22) As reported in the previous papers, lamellar 90° domain structures are present in the grains, and the 90° domain width decreases with decreasing grain size. Figure 4 indicates the relationship of the grain size and the 90° domain width. In accordance with the theoretical model proposed by Arlt and coworkers, the 90° domain width is proportional to the square root of the grain size.1,23) (The 90° domain width can be determined by the minimum in the sum of the domain-wall energy and the elastic energy due to the stress from grain boundaries.) As our experimental result, the 90° domain width was proportional to (grain size)1/2.8 before the poling treatment. Figure 5 shows the domain configurations obtained before and after the poling treatment. The average 90° domain width remained unchanged after the poling treatment. It was confirmed that fine-grained ceramics have a high 90° domain-wall density even after the poling treatment. Since the 90° domain wall is easily moved by an external ac field, the 90° domain wall contributes to the dipole polarization.7,8,24) In addition, the crystal structure around the 90° domain wall is different from the original structure of BaTiO3, and the gradient lattice strain around the 90° domain wall contributes to the ionic polarization, meaning that the crystal lattices soften around the domain wall. This behavior is explained by the polarization rotation mechanism.25–28) In this manner, the 90° domain wall contributes to the dielectric permittivity. For the same reason, the piezoelectric strain constant and elastic compliance of the gradient lattice strain layer around the 90° domain wall are higher than the original values of BaTiO3. Therefore, the fine-grained BaTiO3 ceramics with a high domain-wall density show large d33, k33,  , and

, and  . The enhancement of piezoelectric performance obtained by reducing the grain size down to 1.2 µm is explained by the 90° domain-wall contribution.

. The enhancement of piezoelectric performance obtained by reducing the grain size down to 1.2 µm is explained by the 90° domain-wall contribution.

Fig. 4. Relationship between grain size and 90° domain width in BaTiO3 ceramics.

Download figure:

Standard image High-resolution imageFig. 5. 90° domain configurations in BaTiO3 ceramics with average grain sizes of (a) 4.3 and (b) 1.9 µm obtained before and after poling treatment.

Download figure:

Standard image High-resolution imageIn contrast, for grain sizes below 1.2 µm, the permittivity decreased with decreasing grain size. In our previous studies, we have confirmed decreases in dipole and ionic polarizabilities with decreasing grain size by wideband dielectric spectroscopy.8) In a coarse grain, the 90° domain wall can move relatively easily. However, in a fine grain, the movement of the domain wall is inhibited by the effect of the lattice imperfections on the grain boundary, i.e., the dipole polarization is weakened by domain wall pinning. Moreover, the lattice imperfections suppress the ionic polarization. Since the density of lattice imperfections due to the grain boundary increases with decreasing grain size, the permittivity decreases with decreasing grain size when the grain boundary effect dominates over the domain-wall contribution. The reductions in piezoelectric strain constant and the elastic compliance can be understood in the same manner. In contrast, the piezoelectric voltage constant g33 ( ) increased with decreasing grain size down to 0.6 µm. This is due to the difference in reduction ratio between d33 and

) increased with decreasing grain size down to 0.6 µm. This is due to the difference in reduction ratio between d33 and  , i.e., d33 is less likely to decrease than

, i.e., d33 is less likely to decrease than  with decreasing grain size.

with decreasing grain size.

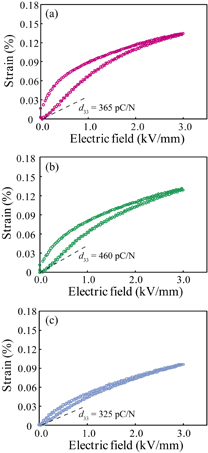

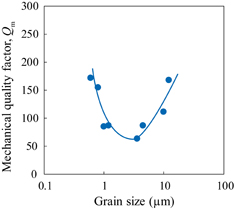

Figure 6 shows the electric-field-induced stains (S–E curves) of BaTiO3 ceramics with various grain sizes. The slopes of S–E curves in the low field range agreed with the S–E curves estimated from d33 measured by the resonance–antiresonance method. It is widely known that the piezoelectric response in ceramics consists of two parts: the intrinsic and extrinsic contributions.29–33) The intrinsic contribution is due to the deformation of the crystal lattice, whereas the extrinsic contribution is mainly due to the non-180° domain-wall motions. In general, the nonlinearity in the S–E curve is due to the extrinsic contribution. When comparing the S–E curves of 3.6 and 1.2 µm, the extrinsic contribution seemed to be hardly different. However, it is difficult to separate the intrinsic and extrinsic contributions from the S–E curves, and therefore, this view may not be true. Another technique, i.e., in-situ XRD measurement under electric field application, or the measurement of direct and converse piezoelectric response at a high frequency, is required for separating the intrinsic and extrinsic contributions. In contrast, for the grain size of 0.6 µm, the nonlinearity in the S–E curve decreased, suggesting the reduction in extrinsic contribution. In addition, the hysteresis of the strain decreased with decreasing grain size, meaning that the piezoelectric loss of fine-grained BaTiO3 ceramics was small at a high electric field. These results suggested that the 90° domain wall tended to be pinned by the grain boundary while the density of the domain wall increased with decreasing grain size. Figure 7 shows the mechanical quality factor Qm estimated by the resonance–antiresonance method. Qm indicated the minimum at around a grain size of 3 µm. By controlling the grain size, a higher Qm (lower mechanical loss) can be obtained.

Fig. 6. S–E curves of BaTiO3 ceramics with average grain sizes of (a) 3.6, (b) 1.2, and (c) 0.6 µm. The dashed lines indicate the S–E curves estimated from d33 measured by the resonance–antiresonance method.

Download figure:

Standard image High-resolution imageFig. 7. Grain size dependence of mechanical quality factor Qm of BaTiO3 ceramics.

Download figure:

Standard image High-resolution imageSince the density and motion of the 90° domain wall can be controlled by the grain size, it can be considered that the grain size control of BaTiO3 ceramics is a type of ferroelectric domain engineering.34,35) For enhancing further the performance of the domain wall, the gain orientation is thought to be important. The piezoelectric properties should be improved by orienting the grains in a direction called the "engineered domain" direction, i.e., the [110] or [111] direction.36) In addition, the domain-wall contribution may be controlled by designing the defect type and its concentration. The effects of grain orientation and defect concentration should be systematically examined in a future.

4. Conclusions

In this study, pure BaTiO3 ceramics with various grain sizes were prepared by conventional and two-step sintering methods. The piezoelectric strain constant d33 increased with decreasing grain size when the grain size was more than 1.2 µm, whereas it decreased when the grain size was below 1.2 µm. The maximum d33 was 460 pC/N, which is approximately three times larger than that of coarse BaTiO3 ceramics, for an average grain size of 1.2 µm. The increase in d33 was well explained by the domain-wall contribution, while the decrease in d33 was understood as the grain boundary effect. On the other hand, the piezoelectric voltage constant g33 increased with decreasing grain size down to 0.6 µm. The piezoelectric constants d33 and g33, and the mechanical quality factor Qm can be controlled by the grain size of BaTiO3 ceramics. Since the grain size effect is expected to be also present in other lead-free perovskite-type materials, we hope that the findings obtained in this study will be helpful for the development of lead-free piezoelectric materials.

Acknowledgements

We would like to thank Sakai Chemical Industry Co., Ltd. for preparing high-purity BaTiO3 powder (BT-01). This work was supported by a Grant-in-Aid for Scientific Research from the Japan Society for the Promotion of Science (JSPS).