Abstract

Novel isotropic and anisotropic thermoplastic magnetorheological elastomers (MRE) were prepared by melt blending titanated coupling agent modified carbonyl iron (CI) particles with poly(styrene-b-ethylene-ethylene–propylene-b-styrene) (SEEPS) matrix in the absence and presence of a magnetic field, and the microstructure and magnetorheological properties of these SEEPS-based MRE were investigated in detail. The particle surface modification improves the dispersion of the particles in the matrix and remarkably softens the CI/SEEPS composites, thus significantly enhancing the MR effect and improving the processability of these SEEPS-based MRE. A microstructural model was proposed to describe the interfacial compatibility mechanism that occurred in the CI/SEEPS composites after titanate coupling agent modification, and validity of this model was also demonstrated through adsorption tests of unmodified and surface-modified CI particles.

Export citation and abstract BibTeX RIS

1. Introduction

Similar to the smart magnetorheological fluids (MRF), magnetorheological elastomers (MRE) consisting of the micrometer-sized magnetically permeable particles in non-magnetic matrices also exhibit rapidly/reversibly controllable mechanical properties under an external magnetic field due to the magnetic interaction of filler particles. However, problems of MRF such as particle sedimentation and fluid leakage can be avoided for MRE [1]. In addition, the particle distribution can be fixed in the fabrication process of MRE: the particles are randomly dispersed (isotropic MRE) or aligned in chains (anisotropic MRE) when MRE is prepared in the absence or presence of an external magnetic field. Besides the superior magnetorheological (MR) effect, MRE are demonstrated to possess other special properties such as electrical resistance, piezoresistivity, thermoresistance, magnetoresistance and magnetostriction [2–5]. These particular features have led to MRE receiving great attention and gaining a wide range of application prospects in the fields of adaptive tuned vibration absorbers and mass dampers, sensors and actuators [6–8].

For the specific MRE applications mentioned above, the matrix and particles in MRE need to be properly chosen to satisfy the requirements for the mechanical properties and the magnitude of the MR effect. In general, the degree of freedom of movement for the magnetic particles is governed by the matrix elastomer and the MR effect is usually smaller in hard matrices than in soft matrices. However, the mechanical properties of soft silicon rubber actually fail to satisfy some practical application requirements [9], and great efforts have been made to further improve the performance of MRE by using other rubbers, such as natural rubber [9], polyurethane (PU) [10–12], isobutylene–isoprene [13] and cis-polybutadiene [14]. In this context, thermoplastic elastomer (TPE) was focused on as the MRE matrix due to its good mechanical properties as well as good recyclability and processability [15].

Carbonyl iron (CI) [16], Fe3O4 [17], Fe nanowires [18] and nickel [5] have been utilized as the magnetizable particles in MRE preparation, in which the CI particle was most commonly used not only because of its excellent magnetic properties (high level of saturated magnetization and low remnant magnetization) but also due to its spherical shape, which helps MRE applications. The chemical features, size and shape of the magnetizable particles obviously influence/govern the properties of MRE materials [16]. Under an applied magnetic field, the field-induced interactions between the magnetizable particles can lead to a change in the particle pre-configuration from isotropic random dispersion to anisotropic ordered chains or complex three-dimensional structures. The volume fraction of CI particles (ϕCI) in the MRE can increase up to 50 vol% [19], but the best volume fraction for achieving good performance of MRE was reported to be ∼27 vol% with the aid of finite-element analysis [20]. Besides choosing a softer rubber matrix [21], adding plasticizer to soften the matrix [22] or introducing compatibilizer to enhance the interactions between filler and matrix [23], modification of CI particles [10, 24, 25] is another method to improve the MR effect of MRE materials. It was reported that when CI particles were modified by anionic, nonionic and compound surfactants, the relative MR effect of MRE based on natural rubber can be increased up to 188% due to the perfect compatibility between particles and rubber matrix and special self-assembly of the particle structure [24]. However, when the CI particles were modified by a silane coupling agent, the MR effect of the MRE based on silicone rubber is unexpectedly decreased, although the modification improves the dispersion of CI particles and the interfacial interactions between the particles and matrix [10, 25].

In our previous research, we prepared isotropic and anisotropic thermoplastic MRE composites based on poly(styrene-b-ethylene-co-butylene-b-styrene) (SEBS) matrix and CI particles and examined their structures and properties [26]. The equilibrium storage modulus (Ge) was obviously enhanced on the addition of CI particles and also on the formation of a chain structure of the particles (in the anisotropic MRE), and the increment of the modulus under a magnetic field was found to exceed 150% for the anisotropic SEBS-based MRE with ϕCI = 21 vol%. In this paper, we prepare novel thermoplastic MRE composites containing poly(styrene-b-ethylene-ethylenepropylene-b-styrene) (SEEPS) matrix and CI particles modified by a titanate coupling agent and examine their microstructure and magnetorheological properties. Similar to SEBS, SEEPS has no C=C double bonds in the EEP block and exhibits good thermal stability and climate resistance (against UV/ozone). However, SEEPS is softer and has a higher working temperature than SEBS, so the SEEPS-based MRE is expected to show a greater MR effect. More importantly, usage of surface-modified CI particles enables us to investigate the influence of the affinity of the particles toward the matrix on the MR effect. In fact, it turns out that the surface modification of CI particles remarkably enhances the MR effect for both isotropic and anisotropic CI/SEEPS composites without sacrificing the toughness of MRE even at a very high filling of particles (ϕCI = 31 vol%). This enhancement of the MR effect is discussed in relation to the interfacial compatibility mechanism occurring between the particle and matrix after particle surface modification, and an adsorption test lends support to this argument.

2. Experimental details

2.1. Materials

A poly (styrene-b-ethylene-ethylenepropylene-b-styrene) (SEEPS) block copolymer (Septon 4055) was purchased from Kuraray Co. Ltd (Japan) and used as received. Its molecular characteristics were Mw = 2.4 × 105,Mw/Mn = 1.01, and S content wS = 30 wt% according to the manufacturer's designation. White oil (Primol N 352; Exxon Mobil Co., USA) was used to plasticize SEEPS. This oil, having an average molecular weight of 480 g mol−1, is a purified mixture of saturated hydrocarbons and is particularly suited for extension of thermoplastic elastomers (TPE) such as SEEPS; dissolving EEP block but precipitating S block. The SEEPS matrix used to prepare MRE composites was a SEEPS/oil 1/4 wt/wt mixture and contained glassy, spherical S domains (at room temperature) that served as physical crosslinks at low T. The EEP mid-blocks formed a rubbery, continuous phase swollen by the white oil.

Commercially available carbonyl iron (CI) particles (FTF-1; Jianyou Hebao Nanomaterial Co. Ltd, China) were used as received. These CI particles had an average particle diameter of 3.5 μm and Fe content of ∼98.3% (manufacturer's designation). The particle density was 7.64 g cm−3, as determined with a pycnometer method. The CI particles were spherical and had a relatively smooth surface, as noted from the scanning electron microscope (SEM) image. Isopropyl tri(dioctylpyrophosphate) titanate (TC201, C51H112O22P6Ti), purchased from Nanjing Shuguang Chemical Group Co. Ltd (China), was used to modify the CI particle surface to enhance the affinity between the CI particles and SEEPS matrix.

To verify the enhancement of the particle/matrix affinity, ethylene–propylene rubber (EPR, Vistalon 878) purchased from Exxon Mobil Corporation (USA) was chosen for the adsorption tests of CI particles in octane (Sinopharm Chemical Reagent Co. Ltd, China). This EPR, possessing a similar molecular structure to the EEP block of SEEPS, had a Mooney viscosity of 52MU and an ethylene concentration of about 60 wt%.

2.2. MRE preparation

Table 1 summarizes the composition of the SEEPS matrix and CI/SEEPS composites. The SEEPS matrix contained 20 wt% SEEPS and 80 wt% white oil. The SEEPS-70CI and SEEPS-80CI composites were mixtures of CI particles in this SEEPS/oil matrix at CI concentrations of wCI = 70 and 80 wt% (ϕCI = 21 and 31 vol%), respectively. The SEEPS-70CI-2Ti and SEEPS-80CI-2Ti composites contained the titanate coupling agent at a concentration of 2 wt% to the CI particle mass, and except for the modifier content the compositions of these composites were the same as those of SEEPS-70CI and SEEPS-80CI composites.

Table 1. Composition of the SEEPS matrix and CI/SEEPS composites without/with titanate coupling agent modification.

| Sample code | SEEPS powder (wt%) | White oil (wt%) | Carbonyl iron (wt%) | TC201 (wt%) |

|---|---|---|---|---|

| SEEPSa | 20 | 80 | 0 | 0 |

| SEEPS-70CI | 6 | 24 | 70 | 0 |

| SEEPS-80CI | 4 | 16 | 80 | 0 |

| SEEPS-70CI-2Ti | 6 | 24 | 68.6 | 1.4 |

| SEEPS-80CI-2Ti | 4 | 16 | 78.4 | 1.6 |

aNote: SEEPS matrix containing white oil; Ti represents the titanate coupling agent (TC201) contained in the CI/SEEPS composites.

The CI particles were pretreated at room temperature with the titanate coupling agent in a blender for 3 min at a low mixing speed and then for 8 min at a high mixing speed. SEEPS powders were mixed with the white oil in a blender for about 10 min at a low speed to allow SEEPS to fully absorb the oil. The white oil selectively swelled the EEP phase of the copolymer but slightly swelled the S phase to give a micellar network structure with discretized, spherical S domains working as the physical crosslinks for the EEP blocks. The CI/SEEPS composites were prepared by melt blending the SEEPS matrix and CI particles without/with the titanate coupling agent modification in a rheometer (Rheocord 900; Haake, Germany), and the change of torque with time during preparation was monitored to evaluate the processibility of the CI/SEEPS composites. At T = 200 °C, a mixing time of 15 min and a rotor speed of 40 rpm were found to be the most suitable processing conditions for these CI/SEEPS composites. The processibility of the CI/SEEPS composites was remarkably improved after the surface modification of CI particles. This notable improvement may be attributed to the formation of a monomolecular layer of titanate coupling agent on the particle surface that enhanced the particle/matrix affinity and highly suppressed particle aggregation.

For the preparation of isotropic MRE, the CI/SEEPS composites were molded into films of 2 mm thickness at 200 °C for 10 min in an ordinary pressing machine in the absence of a magnetic field. For preparation of anisotropic MRE, the CI/SEEPS composites were molded into sheets of 3 mm thickness at 200 °C for 10 min in a home-made magnet–heat-coupled device in the presence of a magnetic field with the intensity ranging from 0 to 1400 mT, just as done in our previous work [26]. The anisotropic CI/SEEPS composites without/with titanate coupling agent modification thus obtained were designated as SEEPS-nCI-m and SEEPS-nCI-2Ti-m, where n represents the CI concentration (in wt%), m represents the magnetic field intensity (in mT) during the fabrication, and 2Ti represents the 2 wt% titanate coupling agent contained in the composites. Similarly, the isotropic CI/SEEPS composites without/with titanate coupling agent modification were named as SEEPS-nCI and SEEPS-nCI-2Ti.

2.3. Morphology observation

The morphology of isotropic and anisotropic CI/SEEPS composites were observed with a JSM-7500FA Scanning Electron Microscope (SEM; JEOL, Japan) operated at an accelerating voltage of 15 kV. Before SEM observation, the CI/SEEPS composite samples, pretreated with liquid nitrogen and freeze-fractured, were coated with a thin gold layer to avoid surface charging.

2.4. Mechanical properties

The tensile test was performed on a CMT6104 Universal Tensile Tester (Sans Testing Machine, China) according to the GB/T 528-1998 standard. The dumbbell-shaped specimens were stretched at a crosshead rate of 500 mm min−1 until rupture. The hardness was measured by a TH200 Hardness Tester (Beijing Time Technology, China) according to the GB/T531.1-2008 standard. Five specimens for each sample were tested to obtain the average value for determination. All the measurements were made at room temperature.

2.5. Magnetic dynamic mechanical analysis (MDMA)

The magnetorheological (MR) properties of the CI/SEEPS composites were examined through a modified Tritec 2000B dynamic mechanical analysis (Triton Technology, UK) system equipped with a home-made electromagnet that could generate magnetic fields of various intensities [26]. This modified DMA system is referred to as MDMA, and the dimension of the sample specimen for tests was 10 mm × 10 mm × 3 mm (length, width and thickness). The measurements were made at frequency of 1 Hz, strain amplitude of 0.0667% and room temperature under the magnetic field to record the field-induced dynamic shear modulus response. The direction of the external magnetic field was perpendicular to the surface of the tested sample. This direction was parallel to the chain structure of the CI particles in the anisotropic CI/SEEPS composites, therefore the modulus measured under the magnetic field detected the response of the composites in the direction perpendicular to those chains.

2.6. Magnetorheological measurements

The rheological behavior of the CI/SEEPS composites was measured at room temperature with a Physica MCR 301 stress-controlled Rheometer (Anton Parr, Germany) possessing a magnetorheological device in the absence or presence of magnetic field. A parallel plate geometry (of non-magnetic titanium) of 20 mm diameter was used. During the measurements, the electromagnetic coil was activated with a current from 0 to 3.0 A, corresponding to a magnetic flux density (ψ) from 0 to 0.66 T inside the gap. To ensure the linear viscoelastic region, a dynamic strain sweep was conducted in the range γ0 = 0.0001–1 (0.01%–100%), where γ0 is the setting strain, at a frequency ω = 5 rad s−1. Magnetic field sweeps were performed from 0 to 0.66 T with a strain amplitude of 1% and a frequency ω = 5 rad s−1. Dynamic frequency sweeps were performed from 100 to 0.1 rad s−1 with a strain amplitude of 1% in the linear régime, and the storage modulus G', loss modulus G'' and complex viscosity η* were recorded as a function of frequency. Steady-state rotary shear measurements were carried out as a function of shear strain amplitude from 0.01 to 25% at ω = 5 rad s−1, and the rheological parameter of shear stress τ was obtained for each shear strain.

2.7. Adsorption test for CI particles

In order to characterize the effect of the titanate coupling agent on the interfacial microstructure in the CI/SEEPS composites, the EPR molecules (having similar molecular structure to the EEP block of SEEPS) were allowed to adsorb on the CI particle (without/with titanate coupling agent modification) surface in octane. In this adsorption test, the CI particles were dispersed in EPR/octane solution with the aid of supersonication and then mechanical shaking for 5 min. After that, the particles were dried to weigh the residue and compared with the initial mass before dispersion, allowing the amount of EPR adsorbed on the particle surface to be determined.

3. Results and discussion

3.1. Morphology observation

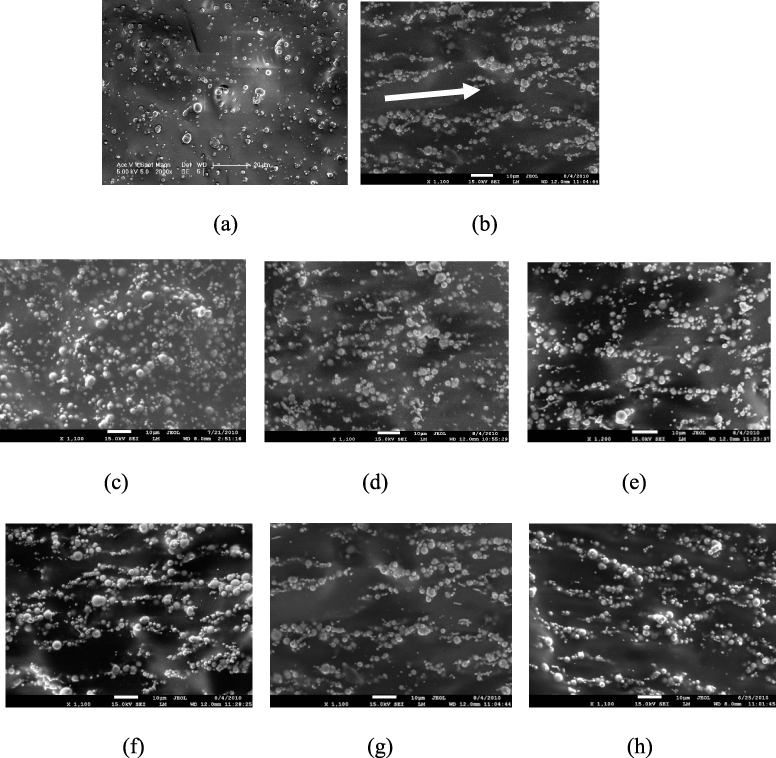

The MR effect of the CI/SEEPS composites should obviously be dependent on the state of the CI particle distribution in the SEEPS matrix. Figure 1 shows the SEM images of the isotropic and anisotropic SEEPS-70CI and SEEPS-70CI-2Ti composites prepared in the absence of a magnetic field and in the presence of a magnetic field of different intensities ψpre as representative for the CI/SEEPS composites. The CI particles (white dots) are uniformly dispersed in the SEEPS matrix without forming large aggregates, and clearly the titanate coupling agent modification further improves the dispersion of the particles in the matrix with the enhancement of their compatibility and interactions. The pretreatment of titanate coupling agent does not obviously change the morphology of the CI/SEEPS composites, but the external magnetic field loading during the anisotropic composite fabrication indeed changes the CI particle distribution greatly, with the formation of chain-like structures aligned in the direction of the magnetic field due to mutual attraction between these magnetizable particles. Clearly, when the SEEPS matrix lost its elasticity and behaved as a soft liquid at 200 °C, the CI particles were reorganized from the random dispersion into an ordered orientated distribution in the matrix. It can also be noted that the degree of alignment and orientation of CI particles is enhanced and the particle chains become longer at larger ψpre. This behavior is naturally expected because the particles are more strongly driven by an increasing ψpre (up to a saturation threshold of ≅600 mT; cf figure 2).

Figure 1. SEM images of the isotropic and anisotropic CI/SEEPS composites without/with titanate coupling agent modification: (a) SEEPS-70CI, (b) SEEPS-70CI–500 mT, (c) SEEPS-70CI-2Ti, (d) SEEPS-70CI-2Ti–100 mT, (e) SEEPS-70CI-2Ti–300 mT, (f) SEEPS-70CI-2Ti–500 mT, (g) SEEPS-70CI-2Ti–700 mT and (h) SEEPS-70CI-2Ti–1400 mT. The white arrow indicates the direction of the external magnetic field. The scale bar in (a) is 20 μm, and the scale bar in the other images from (b) to (h) is 10 μm.

Download figure:

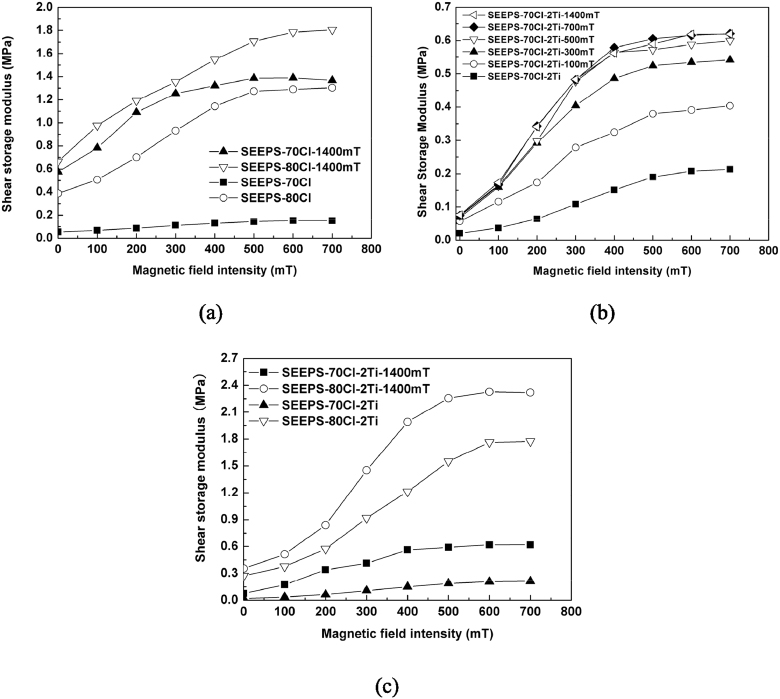

Standard imageFigure 2. Plots of shear storage modulus against magnetic field intensity obtained from MDMA measurements for the isotropic and anisotropic CI/SEEPS composites: (a) without titanate coupling agent modification and ((b), (c)) with titanate coupling agent modification.

Download figure:

Standard image3.2. Mechanical properties

Table 2 lists the mechanical property parameters of the SEEPS matrix and isotropic CI/SEEPS composites. During the tensile test, different from SEEPS-80CI, the SEEPS-80CI-2Ti composite exhibits superior elastomer behavior close to that of the SEEPS matrix, and it is evident that after titanate coupling agent modification such a high filling of magnetic particles (ϕCI = 31 vol%) has almost no influence on the strength and toughness of the SEEPS matrix. The significant difference of the mechanical properties between the SEEPS-80CI and SEEPS-80CI-2Ti composites lies in the change of the interfacial structure with the interaction of the titanate coupling agent. The thicker the interfacial layer is, the fewer soft SEEPS molecular segments (plasticized by white oil) exist, and the harder the CI/SEEPS composites behave. The introduced titanate coupling agent greatly enhances the interfacial compatibility and reduces the thickness of the interfacial layers in the CI/SEEPS composites, thus making the CI/SEEPS composite much softer, and even similar to the SEEPS matrix. Moreover, the titanate coupling agent pretreatment can also significantly reduce the amount of particle aggregation in the matrix, which further decreases the hardness. The detailed compatibility mechanism and microstructural model of the interface formed between the CI particles and SEEPS matrix will be described and demonstrated in section 3.5.

Table 2. Mechanical properties of the SEEPS matrix and isotropic CI/SEEPS composites without/with titanate coupling agent modification.

| Sample code | Elongation at break (%) | Tensile strength (MPa) | Hardness |

|---|---|---|---|

| SEEPS | >1300 | >1.1 | 0 |

| SEEPS-70CI | 1150 | 1.5 | 5 |

| SEEPS-80CI | 1000 | 1.48 | 13 |

| SEEPS-70CI-2Ti | 1400 | 1.82 | 2 |

| SEEPS-80CI-2Ti | 1127 | 0.67 | 4 |

3.3. Magnetic dynamic mechanical properties

One of the most important parameters describing the MR effect of MRE is the shear modulus change caused by the magnetic field. In this study, a modified MDMA was utilized to measure the field-induced dynamic shear modulus response under the magnetic field (ψ ⩽ 1 T) for the isotropic and anisotropic CI/SEEPS composites without/with titanate coupling agent modification, just as illustrated in figure 2. The anisotropic CI/SEEPS composites, coded as SEEPS-nCI(-2Ti)-m with n = wCI in wt% (=70 or 80), m = ψpre (=100–1400 mT) and 2Ti as titanate coupling agent, were pre-structured at 200 °C for 10 min under a magnetic field of intensity ψpre and had a chain-like structure of CI particles (cf figure 1), while the isotropic CI/SEEPS composites, coded as SEEPS-nCI(-2Ti) were hot-pressed in the absence of a magnetic field and had a random and even dispersed structure of CI particles. The shear storage modulus and MR effect of these isotropic and anisotropic CI/SEEPS composites are listed in table 3, in which  is the initial storage modulus without an external magnetic field,

is the initial storage modulus without an external magnetic field,  is the equilibrium storage modulus under a saturated magnetic field, ΔG' is the value of

is the equilibrium storage modulus under a saturated magnetic field, ΔG' is the value of  subtracting

subtracting  , corresponding to the absolute MR effect, and

, corresponding to the absolute MR effect, and  is the relative MR effect.

is the relative MR effect.

Table 3.

Shear storage modulus, MR effect and model parameters of the isotropic and anisotropic CI/SEEPS composites without/with titanate coupling agent modification obtained from the MDMA measurements. (Note:  is the initial storage modulus without an external magnetic field.

is the initial storage modulus without an external magnetic field.  is the equilibrium storage modulus under a saturated magnetic field. ΔG' is the value of

is the equilibrium storage modulus under a saturated magnetic field. ΔG' is the value of  subtracting

subtracting  , corresponding to the absolute MR effect.

, corresponding to the absolute MR effect.  is the relative MR effect. GM,∞' and aψ are the model parameters estimated from the slopes and the intercepts of the plots of ψ2/G' (ψ) versus ψ2.)

is the relative MR effect. GM,∞' and aψ are the model parameters estimated from the slopes and the intercepts of the plots of ψ2/G' (ψ) versus ψ2.)

| Sample code |

(MPa) (MPa) |

(MPa) (MPa) |

ΔG' (MPa) |

(%) (%) |

(MPa) (MPa) |

aψ |

|---|---|---|---|---|---|---|

| SEEPS-70CI | 0.053 | 0.152 | 0.099 | 187 | 0.17 | 0.41 |

| SEEPS-80CI | 0.390 | 1.300 | 0.910 | 233 | 1.39 | 0.38 |

| SEEPS-70CI–1400 mT | 0.166 | 0.802 | 0.636 | 383 | 1.44 | 0.11 |

| SEEPS-80CI–1400 mT | 0.660 | 1.800 | 1.140 | 173 | 1.94 | 0.33 |

| SEEPS-70CI-2Ti | 0.020 | 0.213 | 0.193 | 944 | 0.28 | 1.30 |

| SEEPS-70CI-2Ti–100 mT | 0.057 | 0.404 | 0.347 | 609 | 0.46 | 0.61 |

| SEEPS-70CI-2Ti–300 mT | 0.069 | 0.542 | 0.473 | 686 | 0.59 | 0.37 |

| SEEPS-70CI-2Ti–500 mT | 0.073 | 0.600 | 0.527 | 722 | 0.65 | 0.35 |

| SEEPS-70CI-2Ti–700 mT | 0.074 | 0.621 | 0.547 | 739 | 0.67 | 0.32 |

| SEEPS-70CI-2Ti–1400 mT | 0.076 | 0.619 | 0.543 | 714 | 0.67 | 0.34 |

| SEEPS-80CI-2Ti | 0.271 | 1.775 | 1.504 | 555 | 2.28 | 1.26 |

| SEEPS-80CI-2Ti–1400 mT | 0.355 | 2.320 | 1.965 | 554 | 2.76 | 0.75 |

From figure 2, it can be observed that for these isotropic and anisotropic CI/SEEPS composites, the storage modulus G' exhibits a similar tendency in its change under a magnetic field, increasing rapidly with increasing field intensity ψ up to a threshold value of ψc ≅ 600–700 mT and then leveling off, whether without or with titanate coupling agent modification. Moreover, the threshold value of ψc decreases while G' increases with an increase of CI particle concentration in the composites and ψpre used for anisotropic composite preparation, especially for the CI/SEEPS composites with larger n and m having more ordered and longer chain structures of magnetic particles. This increasing trend of the shear storage modulus with ψ before reaching magnetic saturation is also found for MRE based on natural rubber [27], silicon rubber [28] and PU [22], which agrees well with the theoretical analysis based on the field-induced dipole magnetic forces between the particles. It can be noted from table 3 that, as expected, the relative MR effect ( ) of the CI/SEEPS composites is much higher than that of our previous CI/SEBS composites [26] and other MREs reported before, greater than 180% for the isotropic CI/SEEPS composites and extremely high, as much as 700%, for the anisotropic CI/SEEPS composites. The pre-structuring under a magnetic field not only enhances the degree of alignment and orientation of CI particles in the composites but also elevates the initial storage modulus of the CI/SEEPS composites, thus resulting in a slightly weaker relative MR effect of the anisotropic composites than that of isotropic composites, sometimes unfavorably. The same situation also occurs when the filling of CI particles is high in the SEEPS matrix, and with ϕCI increasing the relative MR effect of the CI/SEEPS composites is somewhat decreased. However, the absolute MR effect (ΔG') of both the isotropic and anisotropic CI/SEEPS composites indeed continuously increases remarkably with the increase of ϕCI and ψpre (before saturation), due to the increasing ordered degree of the magnetic particle alignment and the strengthening of the mutual particle interactions and resultant chain structures. After titanate coupling agent modification, G' of the CI/SEEPS composites is obviously decreased, which should be attributed to the remarkable increase in the softness of the composites originating from the improvement of interfacial compatibility. The resultant significant decrease of

) of the CI/SEEPS composites is much higher than that of our previous CI/SEBS composites [26] and other MREs reported before, greater than 180% for the isotropic CI/SEEPS composites and extremely high, as much as 700%, for the anisotropic CI/SEEPS composites. The pre-structuring under a magnetic field not only enhances the degree of alignment and orientation of CI particles in the composites but also elevates the initial storage modulus of the CI/SEEPS composites, thus resulting in a slightly weaker relative MR effect of the anisotropic composites than that of isotropic composites, sometimes unfavorably. The same situation also occurs when the filling of CI particles is high in the SEEPS matrix, and with ϕCI increasing the relative MR effect of the CI/SEEPS composites is somewhat decreased. However, the absolute MR effect (ΔG') of both the isotropic and anisotropic CI/SEEPS composites indeed continuously increases remarkably with the increase of ϕCI and ψpre (before saturation), due to the increasing ordered degree of the magnetic particle alignment and the strengthening of the mutual particle interactions and resultant chain structures. After titanate coupling agent modification, G' of the CI/SEEPS composites is obviously decreased, which should be attributed to the remarkable increase in the softness of the composites originating from the improvement of interfacial compatibility. The resultant significant decrease of  and increase of ΔG' makes the SEEPS-nCI-2Ti composites possess a much higher absolute and relative MR effect than the SEEPS-nCI composites, whether for the isotropic or anisotropic composites. It is the strong surface activity of titanate coupling agent that allows its molecules to reside at the interface of the CI particles and SEEPS matrix and thus decrease the interfacial tension, which results in a better alignment of CI particles and an enhancement of the MR effect [24]. However, the threshold value of ψc does not change much after particle modification, because the magnetization saturation is related to the magnetic particle interactions and a lesser amount of surface coating will not obviously change the magnetic properties of these CI particles.

and increase of ΔG' makes the SEEPS-nCI-2Ti composites possess a much higher absolute and relative MR effect than the SEEPS-nCI composites, whether for the isotropic or anisotropic composites. It is the strong surface activity of titanate coupling agent that allows its molecules to reside at the interface of the CI particles and SEEPS matrix and thus decrease the interfacial tension, which results in a better alignment of CI particles and an enhancement of the MR effect [24]. However, the threshold value of ψc does not change much after particle modification, because the magnetization saturation is related to the magnetic particle interactions and a lesser amount of surface coating will not obviously change the magnetic properties of these CI particles.

It was found that the magnetically induced modulus GM (ψ) is proportional to the square of the magnetic field intensity ψ (GM(ψ) ∝ ψ2) at low field intensity and approaches the maximum value GM,∞ at high field intensity as the magnetization saturates; these two limiting cases can be phenomenologically described by the following equation:

in which aψ is a material parameter [28]. Through the linear relationship of the plots of ψ2/GM (ψ) versus ψ2, values of GM,∞ and aψ can be estimated from the slopes and intercepts. Figure 3 gives the plots of ψ2/GM'(ψ) versus ψ2 obtained from MDMA measurements (figure 2) for the isotropic and anisotropic CI/SEEPS composites without/with titanate coupling agent modification, and the evaluated parameters of  and aψ are listed in table 3. It can be clearly seen from figure 3 that the MDMA experimental data of the CI/SEEPS composites can be fitted quite well by the phenomenological description in equation (1), with a very good linear relationship when ψ ranges from 200 to 700 mT, whether the composite is isotropic or anisotropic and unmodified or modified by titanate coupling agent. It should also be noted from table 3 that the calculated

and aψ are listed in table 3. It can be clearly seen from figure 3 that the MDMA experimental data of the CI/SEEPS composites can be fitted quite well by the phenomenological description in equation (1), with a very good linear relationship when ψ ranges from 200 to 700 mT, whether the composite is isotropic or anisotropic and unmodified or modified by titanate coupling agent. It should also be noted from table 3 that the calculated  values of the isotropic and anisotropic CI/SEEPS composites are very close to the experimental

values of the isotropic and anisotropic CI/SEEPS composites are very close to the experimental  data, which further verifies the applicability of equation (1) for describing the dependence of the elastic modulus on the induced magnetic field for these SEEPS-based MRE materials. Opposite to the change of

data, which further verifies the applicability of equation (1) for describing the dependence of the elastic modulus on the induced magnetic field for these SEEPS-based MRE materials. Opposite to the change of  decreases with the increase in ϕCI and ψpre and increases after particle modification, but attains a steady value after magnetization saturation, similarly to

decreases with the increase in ϕCI and ψpre and increases after particle modification, but attains a steady value after magnetization saturation, similarly to  . It is evident that both

. It is evident that both  and aψ depend on the concentration and distribution of the magnetic particles as well as the strength of the applied magnetic field.

and aψ depend on the concentration and distribution of the magnetic particles as well as the strength of the applied magnetic field.

Figure 3. Plots of  versus ψ2 obtained from MDMA measurements for the isotropic and anisotropic CI/SEEPS composites: (a) without titanate coupling agent modification and ((b), (c)) with titanate coupling agent modification.

versus ψ2 obtained from MDMA measurements for the isotropic and anisotropic CI/SEEPS composites: (a) without titanate coupling agent modification and ((b), (c)) with titanate coupling agent modification.

Download figure:

Standard image3.4. Magnetorheological behaviors

The MDMA results clearly demonstrate that the MR effect of the CI/SEEPS composites is significantly improved after particle surface modification. In this section, the isotropic CI/SEEPS composites with titanate coupling agent modification were taken as examples to investigate the magnetorheological behaviors, including the dynamic oscillatory shear and steady-state rotary shear responses. As usual, dynamic strain sweep experiments were first carried out to determine the linear viscoelastic region of the CI/SEEPS composites under different ψ (data are not shown here). It is evident that the CI/SEEPS composite with lower ϕCI and under weaker ψ is tougher, with higher deformation for yielding. The strain amplitude of 1% in the linear régime was chosen for all the following magnetic field and frequency sweep tests of the CI/SEEPS composites.

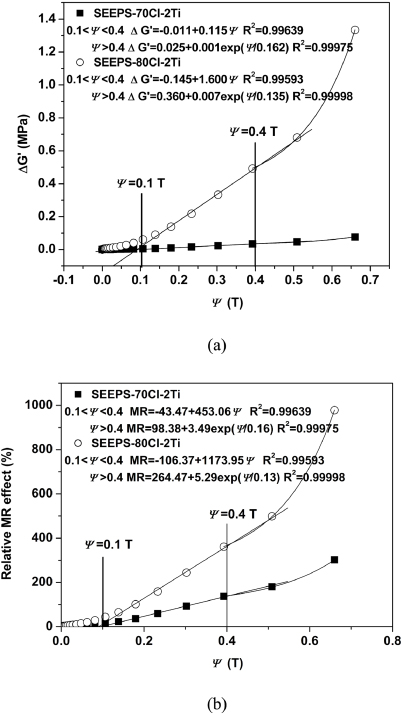

The dynamic magnetic field sweep results of the isotropic CI/SEEPS composites with titanate coupling agent modification are given in figure 4 as the change of storage modulus G' and damping factor tanδ with ψ. It is clear that both ϕCI and ψ greatly affect G' and tanδ of the CI/SEEPS composites. On the one hand, G' and tanδ increase with an increase in ϕCI, particularly at high ψ. More CI particles help to enhance the strength in the ordered structures of particles formed by their mutual magnetic attractions under magnetic field and elevate the elastic modulus of the CI/SEEPS composites correspondingly. The resultant thickening or complexity of the chain-like particle bundles oriented in the magnetic field further improves the damping and vibration isolation effect of the CI/SEEPS composites, with more energy dissipated. Undoubtedly, the increase of ψ obviously strengthens the effect of ϕCI on the elastic and damping behaviors of the SEEPS-based MRE. On the other hand, G' increases continuously with ψ, following a first-order exponential power law, while tanδ first increases with ψ and then drops rapidly after experiencing its maximum value following a second-order power law when ψ > 0.03 T. All the values of coefficient squared (R2) are larger than 0.98, indicating the good fitting of these experimental data. Actually, the existence of a tanδ maximum has also been reported before for the MRE based on natural rubber [27], but the tanδ maximum, ψ for tanδ maximum and the increasing rate of tanδ with ψ are much higher for our CI/SEEPS composites. The absolute and relative MR effect of the CI/SEEPS composites calculated from the storage modulus change caused by the magnetic field are shown in figure 5 as a function of ψ. It can be found in figure 5 that ΔG' and the relative MR effect of the isotropic CI/SEEPS composites exhibit the same change tendency with ψ, increasing linearly when 0.1 < ψ < 0.4 and then exponentially when ψ > 0.4. The greater ψ is, the stronger the magnetic particle associations are, and the greater the MR effect of the SEEPS-based MRE is. It appears that the rate of increase of the MR effect with ψ greatly depends on both the concentration and surface features of the particles and the type of matrix. Different from the MRE based on silicone rubber, our SEEPS-based MRE shows a greater rate of increase in the MR effect at higher ψ above 400 mT than at lower ψ [25].

Figure 4. Change of (a) the storage modulus G' and (b) damping factor tanδ with the magnetic field intensity ψ, obtained from the dynamic magnetic field sweeps for the isotropic CI/SEEPS composites with titanate coupling agent modification.

Download figure:

Standard imageFigure 5. Change of (a) absolute MR effect (ΔG') and (b) relative MR effect with the magnetic field intensity ψ, obtained from the dynamic magnetic field sweeps for the isotropic CI/SEEPS composites with titanate coupling agent modification.

Download figure:

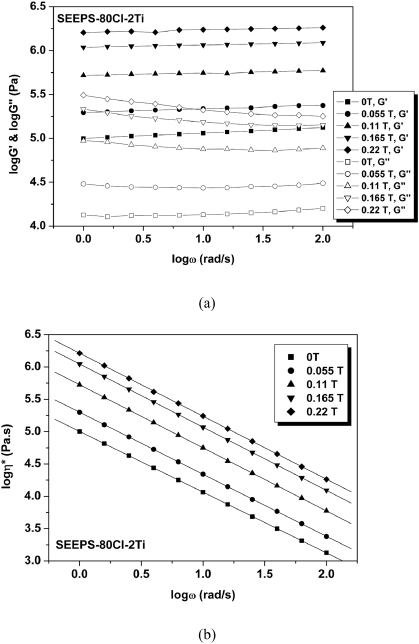

Standard imageFigure 6 shows the linear viscoelastic behaviors of isotropic CI/SEEPS composites with titanate coupling agent modification under different ψ obtained from the dynamic frequency sweeps. All the isotropic CI/SEEPS composites exhibit similar changes of storage modulus G' and complex viscosity η* with frequency ω at different ψ, so just the results of SEEPS-80CI-2Ti composite are shown here as a representative. Similar to the results of the SEBS matrix and CI/SEBS composites [26], when ω varies from 100 to 0.1 rad s−1,G' of the SEEPS matrix and CI/SEEPS composites is always one order of magnitude greater than G'', shows an elastic plateau at low ω with a much lower slope than 2 (G' ∝ ω0.006–0.061), either in the absence or presence of magnetic field, and increases with an increase in ϕCI and ψ, as it does in MDMA measurements. The elastic plateau of G' should be attributed to the entanglement network of the middle EEP blocks swollen with the white oil and physically crosslinked by the spherical domains of the end-S blocks. The addition of the magnetic field makes the particles reorganize to be chain-like clusters along the magnetic field direction, and the enhancement in the strength of these oriented particle bundles at stronger magnetic field endows this kind of MRE with a greater elastic response and higher modulus and viscosity. The particle associations orientated in the magnetic field direction can be clearly seen in the microscope images in figure 1, especially at high ψ. The increase of modulus and viscosity is more remarkable for the SEEPS-80CI-2Ti composite due to the increase in the strength of the particle interconnections at higher ϕCI. Moreover, the complex viscosity of all the CI/SEEPS composites decreases linearly with frequency, following a power law η* ∝ ω0.94–0.98 in the absence or presence of a magnetic field.

Figure 6. Linear viscoelastic properties obtained from the dynamic frequency sweeps for the isotropic SEEPS-80CI-2Ti composite under different magnetic field intensity: (a) logG' and logG'' versus logω and (b) logη* versus logω.

Download figure:

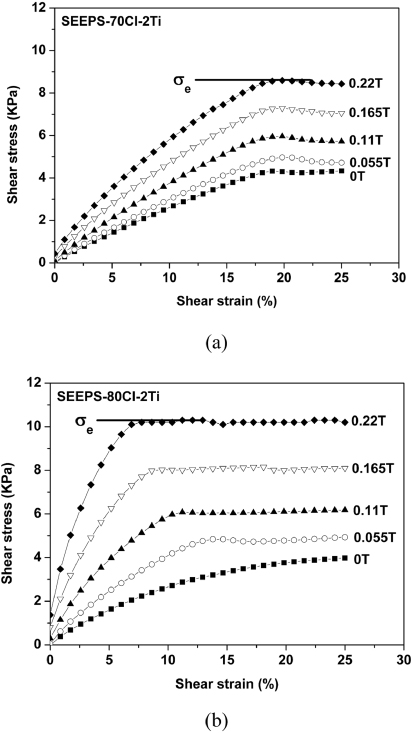

Standard imageFigure 7 shows the shear stress–shear strain curves of the isotropic CI/SEEPS composites with titanate coupling agent modification under different ψ obtained from the steady-state shear measurements. All the CI/SEEPS composites exhibit stress growth in the absence of a magnetic field and slight stress overshoot before reaching steady state in the presence of a magnetic field, similar to the steady shear response of the MRE based on silicone rubber [29]. In the linear viscoelastic test (figure 6), the CI/SEEPS composites behave as a solid under small strain, and the steady state seen at large strains here (figure 7) should characterize highly nonlinear, plastic flow as well as slippage in the composites, especially when the CI particle forms rigid chain-like structures in the presence of a magnetic field. The peak strain for the stress overshoot does not change much with ψ, centering around 20% for the SEEPS-70CI-2Ti composite, but decreases remarkably from 13.8% to 6.9% when ψ increases from 0.055 to 0.22 T for the SEEPS-80CI-2Ti composite. The stress overshoot of the CI/SEEPS composites appears to be greatly affected by the shear orientation of the particle chains formed under a magnetic field and the slippage between the particle chains and the SEEPS matrix. As for the SEEPS-70CI-2Ti composite, the amount of SEEPS seems to be sufficient to firmly grip the shear-oriented particle chains and suppress their slippage, so that the peak strain is hardly affected by the change in ψ. However, as for the SEEPS-80CI-2Ti composite, the reduction of amount of SEEPS makes some particle chains lose their firm grip in the rubber matrix, and the resultant slippage of particle chains leads to an obvious decrease of the peak strain. Similar to the dynamic modulus and viscosity, the shear stress still significantly increases with an increase of ϕCI and ψ. The equilibrium shear stress (σe) in steady state increases with ψ exponentially, and the increasing rate of σe with ψ is much faster for the SEEPS-80CI-2Ti composite with higher ϕCI.

Figure 7. Change of the shear stress with shear strain obtained from the steady-state shear measurements for the isotropic CI/SEEPS composites with titanate coupling agent modification under different magnetic field intensity: (a) SEEPS-70CI-2Ti and (b) SEEPS-80CI-2Ti.

Download figure:

Standard image3.5. Interfacial compatibilization mechanism

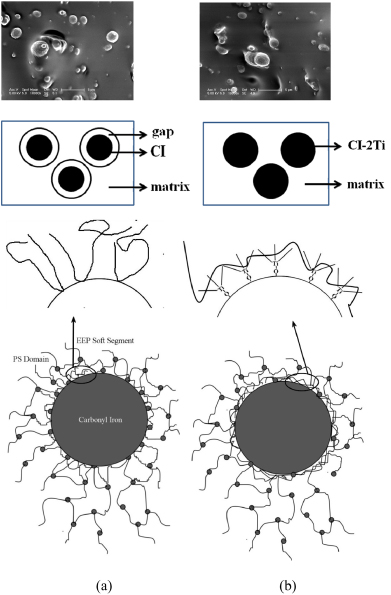

An interphase exists between the CI particles and SEEPS matrix in the CI/SEEPS composite, and it is apparent that the modification of titanate coupling agent on the CI particle surface obviously improves the interfacial compatibility between the particle and matrix, thus remarkably softening the CI/SEEPS composites and enhancing their MR effect. The difference of the interfacial microstructure directly results in a difference in the mechanical, DMA and rheological properties between the unmodified and modified CI/SEEPS composites. The adsorption of matrix layers on the polar CI particle surface would have occurred with the S blocks being polar compared to the EEP block and white oil, just as mentioned in our previous study of CI/SEBS composites [26]. After modification, the titanate coupling agent molecules adsorbed on the particle surface significantly enhance the affinity of CI fillers with the SEEPS matrix, so that the interfacial layer thickness and possible particle aggregations are then greatly reduced. The oxygen atoms contained in the hydrophilic groups of titanate coupling agent can form chemical adsorption on the surface of CI particles and strengthen the particle hydrophobicity, and the hydrophobic groups of the titanate coupling agent can combine with the SEEPS molecules by nonpolar interactions, which results in a significant improvement in the compatibility between the particles and matrix.

In order to describe the interfacial compatibility mechanism occurring in the SEEPS-based MRE after particle surface modification, we put forward the microstructural models for both unmodified and modified CI/SEEPS composites in figure 8. When the carbonyl iron particles are dispersed in the SEEPS matrix, PS hard segments self-assemble to form PS micro-domains anchored on the CI particle surface, and EEP soft segments that could be swollen by white oil are adsorbed on the CI particle surface too. We believe that the adsorption mode of EEP soft segment on the particle surface should be different for the unmodified and modified CI/SEEPS composites. For unmodified CI particles, EEP soft segments are adsorbed on the particle surface in a single point mode, and more SEEPS molecular chains are involved to form a soft and thick interfacial layer, thus leading to a remarkable increase in the modulus and stiffness (strength and hardness) and a corresponding decrease in the toughness and softness of SEEPS-based MRE. The resultant obvious gaps between the CI particles and SEEPS matrix due to their poor interactions causes loss of magnetic energy and the microstructure is less changed under the magnetic field [25], as represented by the lower absolute and relative MR effect. For modified CI particles, a monomolecular layer of titanate coupling agent is formed on the particle surface, EEP soft segments are adsorbed on the particle surface in a covering mode due to the affinity of EEP segments and titanate coupling agent and the resultant van der Waals interactions, therefore less SEEPS molecular chains are involved to form a hard and thin interfacial layer. Besides improving the dispersion of CI particles in the SEEPS matrix, the enhancement of the interfacial compatibility between the particles and matrix also makes the CI/SEEPS composites retain the original toughness and softness of the SEEPS matrix, which allows the CI particles to align in the magnetic field direction easily and makes the SEEPS-based MRE exhibit superior MR effect under a magnetic field. It can also be clearly seen from the SEM images under higher magnification of the isotropic SEEPS-70CI and SEEPS-70CI-2Ti composites in figure 8 that the gaps between the SEEPS matrix and CI particles have been greatly reduced and even disappear after particle modification.

Figure 8. Microstructure illustration of the interphase between carbonyl iron particles and the SEEPS matrix in the isotropic CI/SEEPS composites: (a) carbonyl iron particles and SEEPS matrix and (b) titanate coupling agent modified carbonyl iron particles and SEEPS matrix. White oil is not shown here. The top plots are SEM images of isotropic SEEPS-70CI (left) and SEEPS-70CI-2Ti (right) composites with a magnification of 10 000× and scale bar of 5 μm.

Download figure:

Standard imageEPR (ethylene–propylene rubber, non-crosslinked) has a similar structure to that of EEP segment, and octane has similar chemical properties to those of white oil. In order to check the adsorption mechanism of EEP segments on the CI particle surface, by supersonication we dispersed the unmodified CI particles (CI) and titanate coupling agent modified CI particles (CI-2Ti) in EPR/octane solution respectively for comparison, analogous to the dispersion of CI and CI-2Ti particles in EEP/white oil phase for the CI/SEEPS composites. After shaking for enough time, drying and weighing the residue solid, it is found that about 3.4 mg EPR molecules is adsorbed on the unmodified CI particles (40 mg), while 0.6 mg EPR molecules is adsorbed on the modified CI particles (40 mg). This result further demonstrates our conclusion that more SEEPS molecules are adsorbed on the unmodified CI particle surface than those on the modified CI particle surface described above in the microstructural model.

4. Conclusion

Similar to the CI/SEBS composites we previously reported, the CI particles are uniformly dispersed in the SEEPS matrix, and reorganize into an ordered chain-like structure along the magnetic field direction during the anisotropic composite fabrication, with a higher degree of orientation and longer particle chains at larger ψ. However, superior to the CI/SEBS composites, the CI/SEEPS composites exhibit a much higher magnetorheological (MR) effect, greater than 180% for the isotropic CI/SEEPS composites and extremely high, as much as 700%, for the anisotropic CI/SEEPS composites. After the CI particles were modified by the titanate coupling agent to enhance their compatibility with the SEEPS matrix, it is found that the obtained CI/SEEPS composites become much softer with a higher MR effect and show almost the same mechanical properties as the SEEPS matrix does, without sacrificing toughness, even with such a high filling of the solid CI particles as 80 wt%. These phenomena should be attributed to the change in the interfacial structure formed between the CI particles and the SEEPS matrix. The introduced titanate coupling agent enhances the affinity of the CI particles toward the SEEPS matrix, changes the adsorption of soft EEP segments on the particle surface from single point mode to cover mode, and obviously decreases the thickness of the interfacial layers in the CI/SEEPS composites. These influences are very helpful in avoiding the magnetic energy loss originating from the gaps, allowing the CI particles to align in the magnetic field direction more easily, and making the SEEPS-based MRE exhibit a superior MR effect under a magnetic field.

Acknowledgments

This research was supported by the Science and Technology Research and Development Programme from the Ministry of Railways of China (grant No. J2011J002), Minhang District-Shangai Jiao Tong University Science and Technology Cooperation Special Fund. The authors also thank the Instrumental Analysis Center of Shanghai Jiao Tong University for assistance with the measurements.